Which manufacturing method should you use? Metal casting? Forging? Stamping? Machining?

Here are the pros and cons of metal casting to help you decide when to choose casting as your manufacturing method.

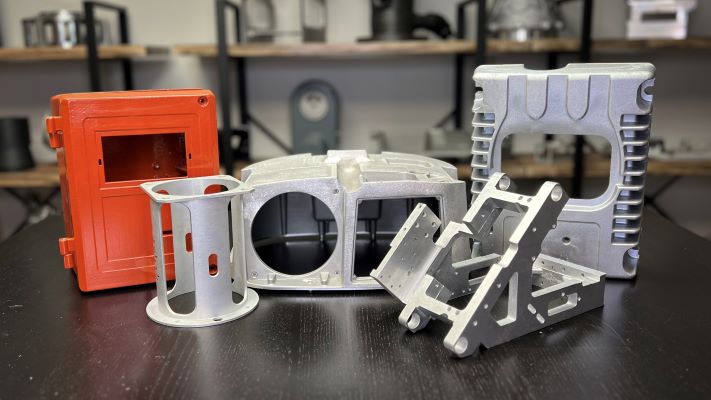

Photo: 5 aluminum permanent mold castings

Metal casting is often more cost effective than other manufacturing methods for high volume production. This process can efficiently achieve high production rates, making it ideal for mass production applications that require large quantities.

The thickness, shape, and function of your design may lend itself to casting rather than stamping or fabrication. Metal casting can handle the production of high-performance, complex shapes and intricate designs that could be challenging or expensive to produce using methods like machining or forging.

For example, investment casting is great for tiny intricate castings, and permanent mold casting is great for large, tight-tolerance castings. Both metal casting methods produce a strong, functional casting with a smooth surface finish.

Producing large parts often proves more cost-effective and feasible with metal casting than other manufacturing methods. Part size is often limited by the equipment used to produce it, like a CNC machine’s footprint. Machining large parts form billet can also be time consuming and costly due to material waste and extensive machining operations. Casting minimizes waste for large parts, cuts down machine time, and can accommodate extraordinary dimensions. For example, sand casting molds can produce the largest castings, like large construction or agriculture equipment components.

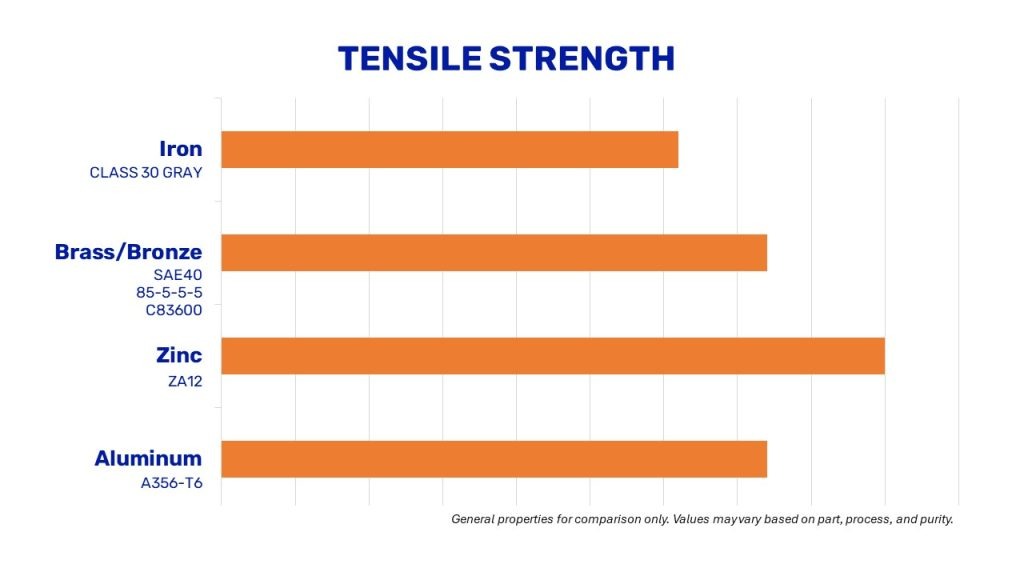

A wide range of metals and alloys can be used in casting, so you can choose a material that meets your specific performance requirements. You can cast iron, steel, aluminum, zinc, brass, copper alloys and more. At BPI, we cast aluminum A356, zinc ZA5, and zinc ZA12.

Casting is not always the most cost-efficient option for low volume production. Metal casting costs include tooling, material, secondaries, and labor.

Sand or investment casting are often more cost efficient than permanent mold or die casting for low-volume production. Especially if you plan on gradually scaling up production, sand casting is a great way to get started.

But for a hand full of simple components or prototyping, other manufacturing methods like machining might be more suitable due to lower tooling costs and shorter lead times.

When planning for future growth, keep in mind each manufacturing method has different design requirements. For example, metal casting requires draft, but machining does not.

Metal castings require a mold or tool, which is an additional cost. This may impact the cost-effectiveness of low-volume production runs. However, manufacturers see a return on investment on tooling cost for high volume production.

Metal casting processes can have longer lead times compared to 3D printing or other manufacturing methods, because it takes time to create custom tooling and fixtures. The exact lead time depends on the casting process. For example, investment casting requires the creation of a wax pattern and ceramic shell.

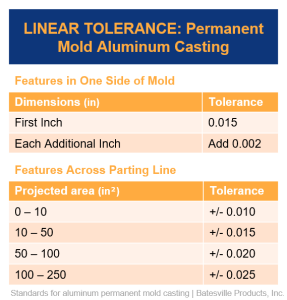

Like other manufacturing methods, metal castings may require secondary operations such as machining, polishing, or powder coating to hit final tolerances, remove parting lines, or meet aesthetic requirements. But because metal casting produces a near-net shape, a parts require less machining time than machining from stock.

Some assembled castings meet requirements as-cast and might be able to skip secondary operations.

Every part is custom! It’s important to note that the advantages and disadvantages can vary based on the part design, casting process, material, and requirements of the part being produced.

Therefore, it’s best to consult with an expert to determine if metal casting is right for you. Call or email us today!