More and more of maritime gear is switching to aluminum casting components. Why? Aluminum is lightweight and durable with high-end finishing options, and permanent mold casting is cost effective for manufacturing complex designs at the volumes needed in the marine industry.

Aluminum castings are common in commercial marine equipment, rescue vessels, subsea operations, boat lighting, U.S. Navy projects, and more. Aluminum offers several key benefits:

Aluminum is naturally rust-resistant, unlike iron or steel. This natural corrosion resistance is great for underwater castings or boating components.

Finishes and coatings and further protect aluminum against other forms of corrosion.

Aluminum can be polished to a smooth shine, or shot blasted for a full-coverage texture.

Aluminum castings can also be powder coated, painted, anodized, or chromated to match the aesthetics of marine equipment.

These same corrosion resistance and finishing properties are why aluminum castings are used in lighting equipment, whether on the coast or sea.

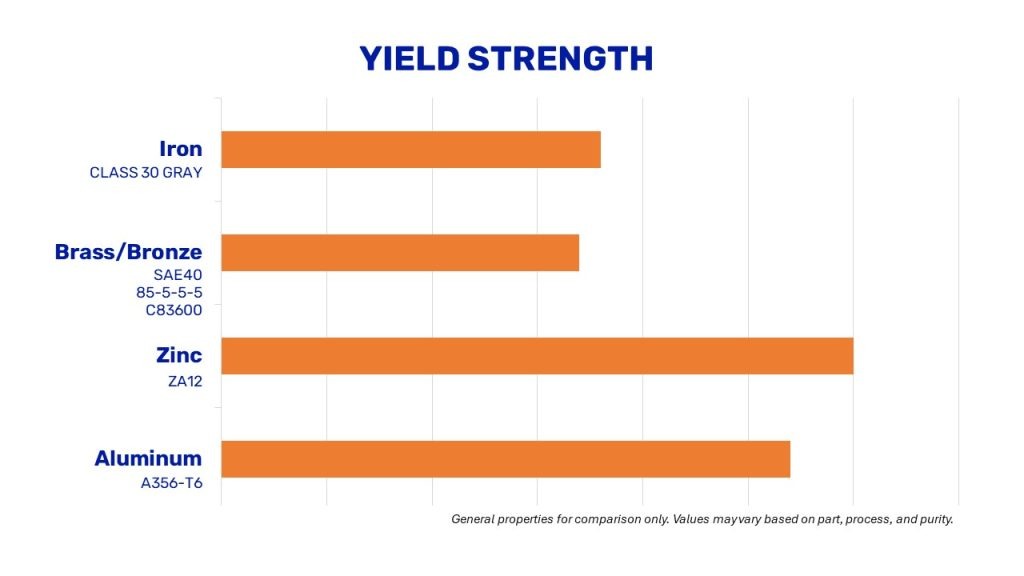

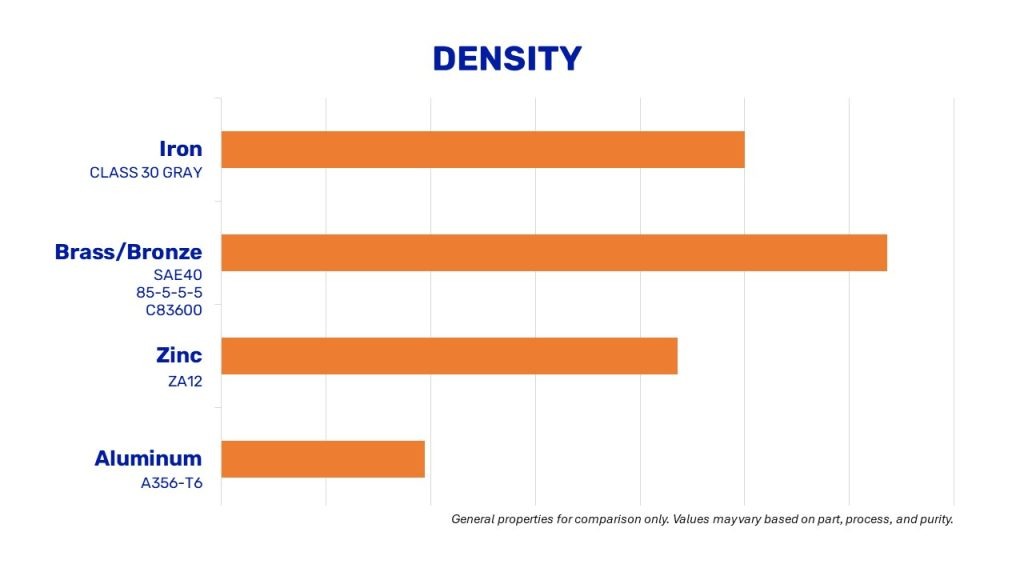

Aluminum has a high strength-to-weight ratio, making it light yet strong. T5 or T6 heat treating aluminum castings further enhances their mechanical strength properties.

Permanent mold casting is ideal for the complex shapes and sizes of custom workboat equipment.

One design feature you can take advantage of in permanent mold casting is fins. Fins further enhances aluminum’s natural thermal conductivity by aiding heat dissipation.

Permanent mold casting is known for its smooth as-cast surface finish. The reusable steel mold creates a smoother surface than the sand mold used in sand casting.

The surface can be further enhanced with polishing, powder coating, anodizing, chromating and more. This high-quality surface finish matches the high-quality features of boats, ocean vessels, submarines, and lighthouses.

Permanent mold casting is cost effective for moderate volume production, like the volumes seen in the maritime industry.

Permanent mold casting uses reusable steel molds. You’ll see a better return on your tooling investment if you’re producing hundreds or thousands of pieces per year. We recommend sand or investment casting for lower volume production.

Get a free quote today for aluminum and zinc casting! Call 812-537-2275 or contact our casting experts today.