This lid is a critical piece of a commercial-grade fryer, commonly used in fast-food restaurants and commercial kitchens. To fry chicken all day long, the equipment must be durable, reliable, and food-safe. That’s why we use aluminum A356 permanent mold casting to manufacture this component.

A356 is food-grade aluminum. Its natural corrosion resistance and lightweight makes aluminum the perfect material for kitchen and restaurant equipment. Aluminum castings are long-lasting, high-performance products that meet the unique demands of commercial kitchens.

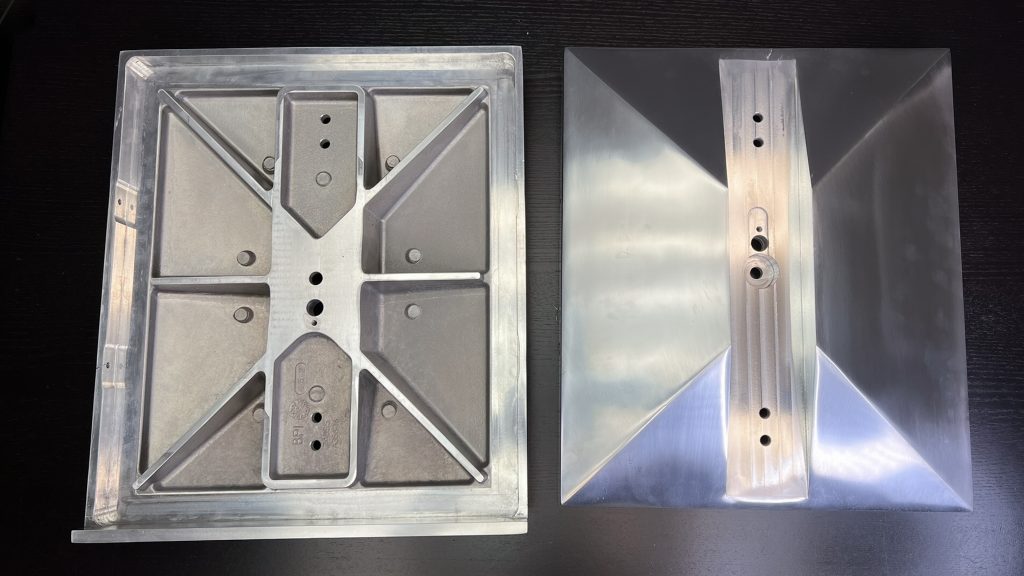

The geometry and size of this casting is perfect for reverse tilt permanent mold casting. As demonstrated by the pour and solidification simulation, the reverse tilt process directs shrinkage and porosity into the riser, resulting in a dense and defect-free casting.

The permanent mold casting process offers several benefits to food service equipment:

In the food industry, equipment must be free from porosity and offer a smooth, easy-to-clean surface to avoid any risk of food entrapment.

This lid must be dense for pressure-frying and long-lasting performance. The finite element analysis and casting simulation helps us build the best mold and pouring process possible, while a lab inspection process verifies our high-quality guarantee.

This casting goes through heat treatment to enhance mechanical properties, secondary machining for assembly specifications, lab testing for quality assurance, and finishing for a clean look.

This aluminum fryer lid is a prime example of why permanent mold casting is the preferred manufacturing method of the food service industry. Dense aluminum castings offer the reliability, high performance, and cleanliness required for commercial kitchen equipment.