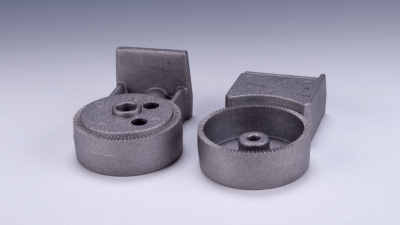

This aluminum casting is for parking lot lighting equipment. The metal casting is small, with strong interlocking teeth.

The customer chose aluminum permanent mold casting because of its precision, durability, and consistent quality.

Outdoor lighting fixtures must be strong and durable, withstanding harsh outside environments while providing reliable lighting.

For this component to function effectively, it requires precisely crafted teeth to ensure that pairs of castings interlock tightly. Consequently, the customer needed a supplier capable of consistently producing a precise and repeatable product.

The customer chose aluminum permanent mold casting for several reasons:

The casting design includes tiny, yet strong teeth for interlocking two identical castings together, providing a secure and seamless assembly process. Permanent mold casting is known for its tight tolerances, which can be even further enhanced with secondary machining.

Despite their small size and light weight, aluminum castings offer exceptional strength properties and corrosion resistance, ensuring the longevity and reliability of parking lot lighting fixtures even in challenging outdoor conditions.

With a reusable permanent mold, manufacturing is consistent and repeatable. Modern robotics and automation help make components even more precise and consistent in quality. This is key for identical interlocking castings.

Permanent mold casting is ideal for complex, high-quality components in moderate to high quantities, reducing manufacturing costs and enhancing overall competitiveness in the lighting industry.

Compare permanent mold to sand casting, die casting, investment casting, or machining from billet.

Lighting industry components come in all shapes and sizes – from these small interlocking castings to large decorative street lamp heads. But the complexity, quality, and quantities needed in outdoor lighting components makes permanent mold casting the top manufacturing method.

By partnering with Batesville Products, this lighting equipment manufacturer enjoyed all the benefits of aluminum permanent mold casting: precision, strength, durability, and repeatability.