How does A356-T6 compare to zinc ZA12, class 30 gray iron, brass SAE40 or bronze 85-5-5-5 (C83600)?

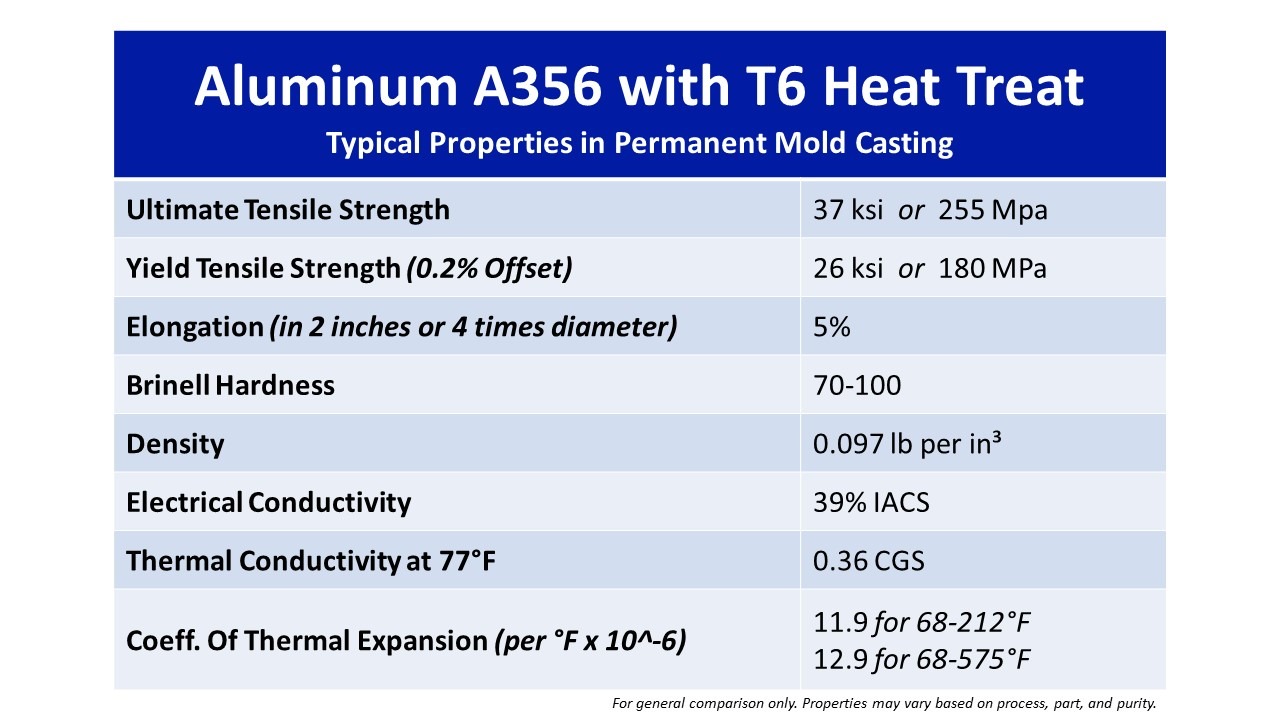

Here are the typical mechanical and physical properties of an aluminum A356 permanent mold casting with a T6 heat treatment, and how it compares to other casting alloys.

Note that these are general properties meant for comparing casting alloys, and the exact values may vary based on part, process, and purity.

For a comparison of aluminum alloys (A356-T6, A380, and 319) check out this guide.

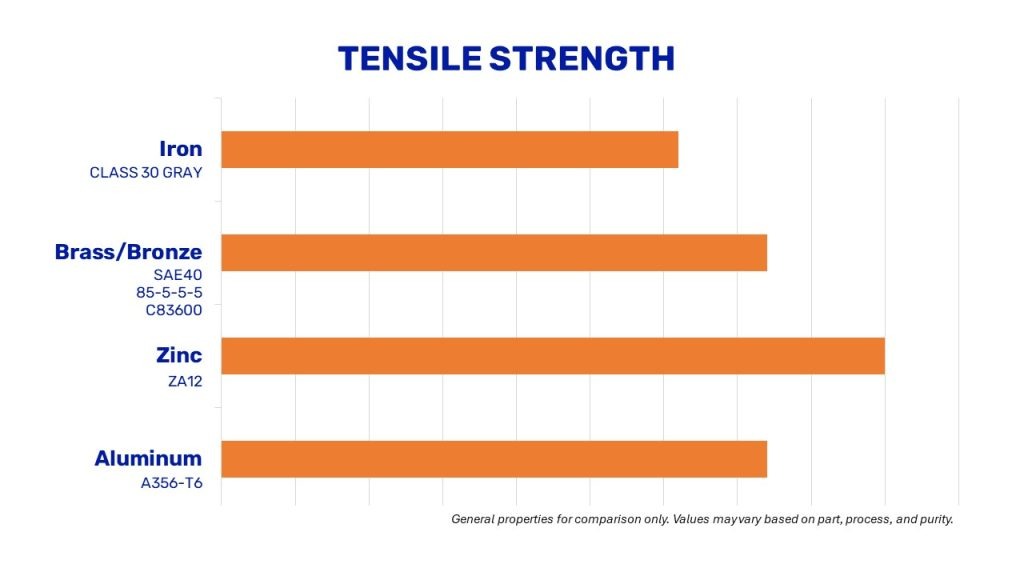

The ultimate tensile strength of an A356 aluminum casting with a T6 heat treatment is typically 37 ksi (255 MPa) in permanent mold casting.

A356-T6 tensile strength is comparable to brass SAE40 or bronze 85-5-5-5 (C83600). A356-T6 permanent mold castings are stronger than class 30 gray iron sand castings, but not as strong as zinc ZA12 castings.

High tensile strength castings are strong and durable. By using a high tensile strength alloy, you can build a durable product with less material, which optimizes weight and cost.

Aerospace, marine, defense, and construction industries often have harsh conditions that require high tensile strength alloys.

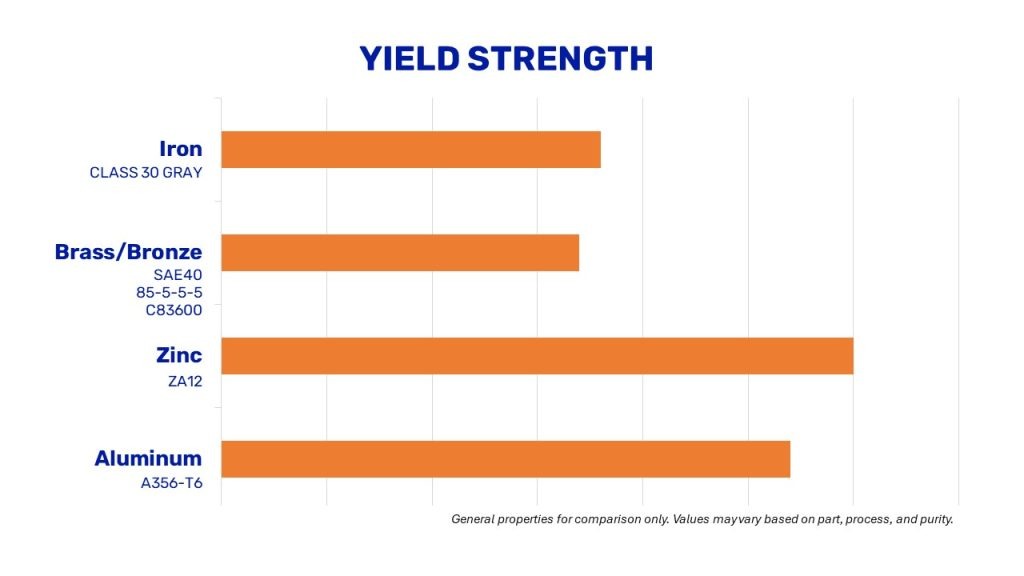

The yield tensile strength (measured using the 0.2% offset method) of an A356 aluminum casting with a T6 heat treatment is typically 26 ksi (180 MPa) in permanent mold casting.

A356-T6 permanent mold casting yield strength is stronger than class 30 gray iron, brass SAE40, and bronze 85-5-5-5 (C83600) sand castings. But, it’s slightly weaker than zinc ZA12 castings.

A high yield strength means more structural integrity, which is important in industries such as oil and gas, mining, infrastructure, and machinery.

Like high tensile strength, high yield strength alloys can make durable products with less material, leading to weight and cost savings.

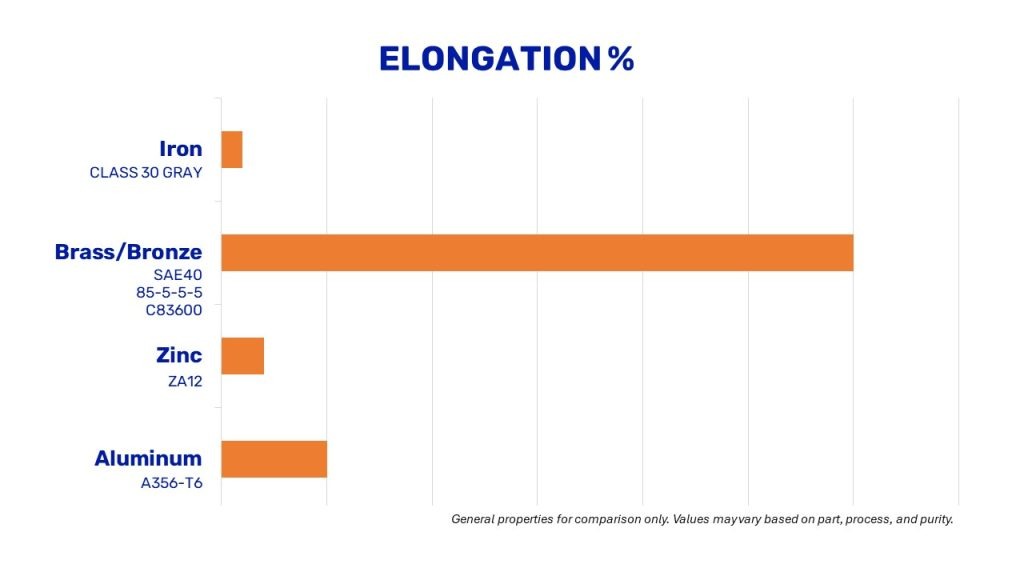

The elongation (measured over 2 inches or 4 times diameter) of an A356 aluminum casting with a T6 heat treatment is typically 5% in permanent mold casting.

A356-T6 elongation percentage is higher than zinc ZA5 and ZA12 and class 30 gray iron, but much lower than brass SAE40 or bronze 85-5-5-5 (C83600).

A high elongation percentage indicates good ductility, meaning the material will stretch before breaking. This is especially desirable in applications such as piping, wiring, and cabling.

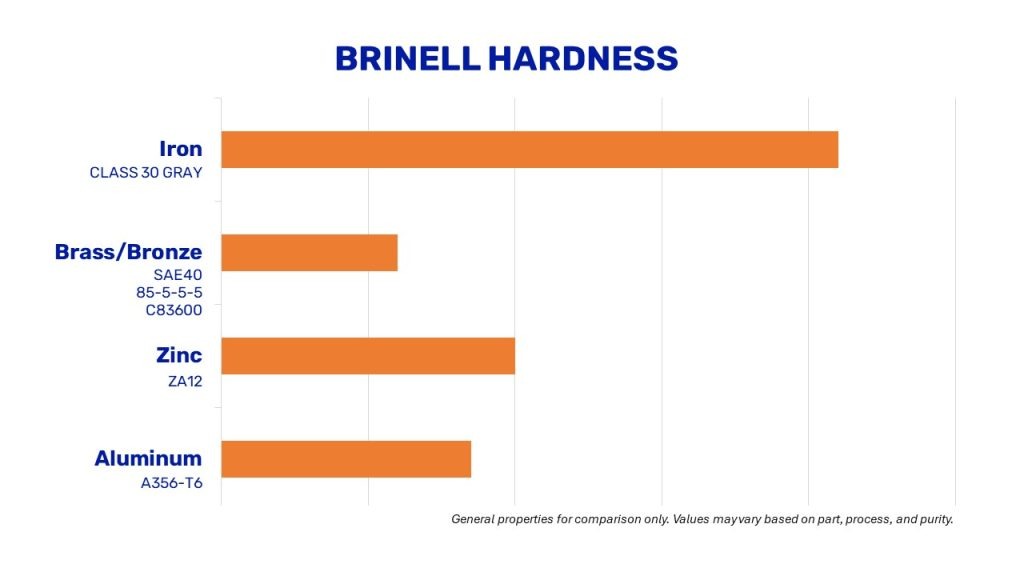

The Brinell hardness (measured with a 500-kgf load and a 10-mm ball) of an A356 aluminum casting with a T6 heat treatment is typically 70-100 in permanent mold casting.

A356-T6 is harder than brass SAE40 or bronze 85-5-5-5 (C83600), but not quite as hard as zinc ZA12. Class 30 gray iron is significantly harder than A356-T6.

A high Brinell Hardness means more wear resistance, high durability, and better machinability. Alloys higher on the Brinell Hardness Scale are common in construction equipment, agriculture, and utility industries.

Here are the typical physical properties of each alloy. Again, these typical properties are meant for comparison, and the exact values will vary based on part and process.

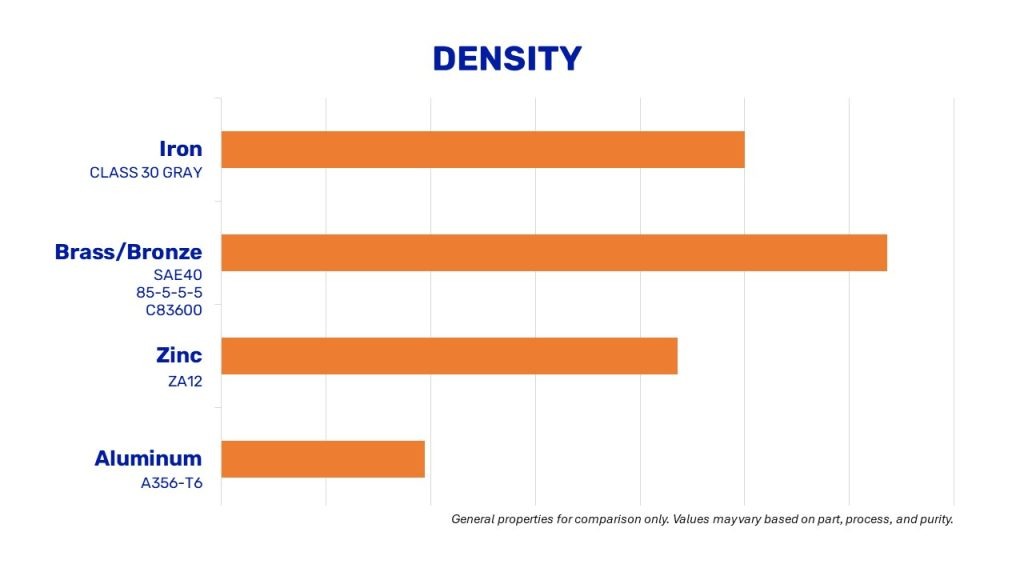

The density of A356 aluminum with a T6 heat treatment is typically 0.097 pounds per cubic inch. The density of an A356-T6 casting will vary depending on the casting process, foundry practices, and part requirements.

The alloy A356-T6 is less dense than zinc ZA12, brass SAE40, bronze 85-5-5-5 (C83600), or class 30 gray iron.

The lower density of A356-T6 is favorable if you’re looking for a lightweight product with high strength. But, some applications require denser and heavier alloys, like zinc medical cart bases.

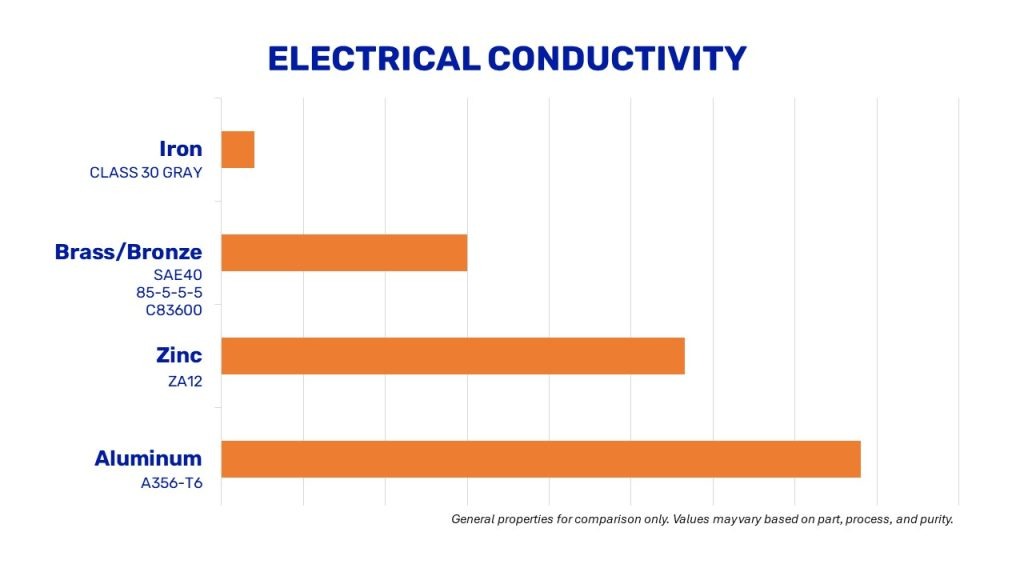

The electrical conductivity of A356 aluminum with a T6 heat treatment is typically 39% IACS.

A356-T6 is more electrically conductive than iron, zinc ZA5 and ZA12, brass SAE40, and bronze 85-5-5-5 (C83600).

The electrical conductivity of an A356-T6 casting may come in handy for electrical enclosures, grounding components, renewable energy equipment, or electric motor and generator parts.

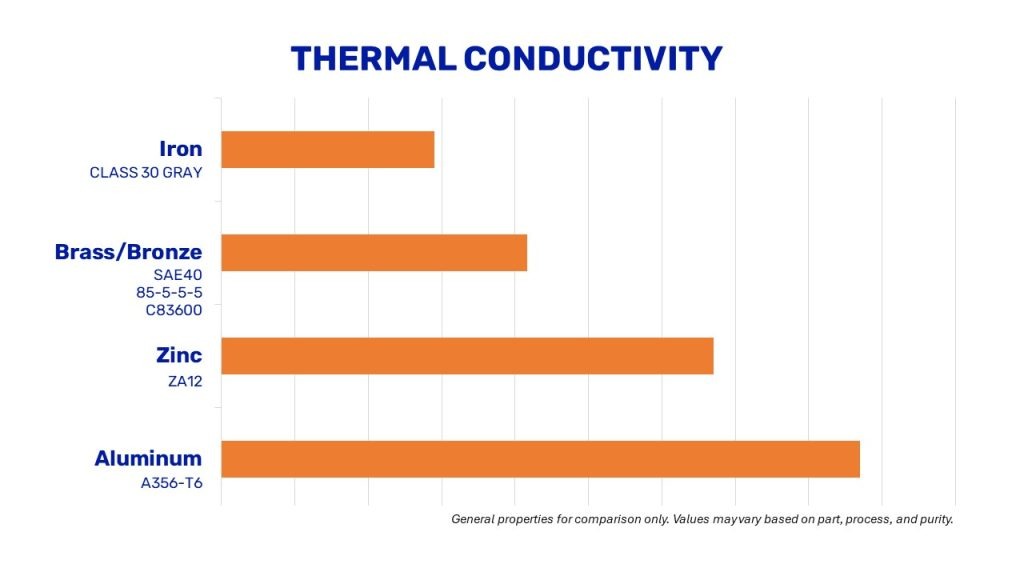

The thermal conductivity of A356 aluminum with a T6 heat treatment is typically 0.36 CGS at 77 degrees Fahrenheit.

A356-T6 is more thermally conductive than iron, zinc ZA5 and ZA12, brass SAE40, and bronze 85-5-5-5 (C83600).

In industrial machinery, renewable energy systems, HVAC systems, and electronic applications, thermal conductivity is critical to prevent overheating.

While the alloy itself may have effective heat dissipation, the design of the part can also play a role in thermal conductivity. For example, fins can help a casting transfer heat.

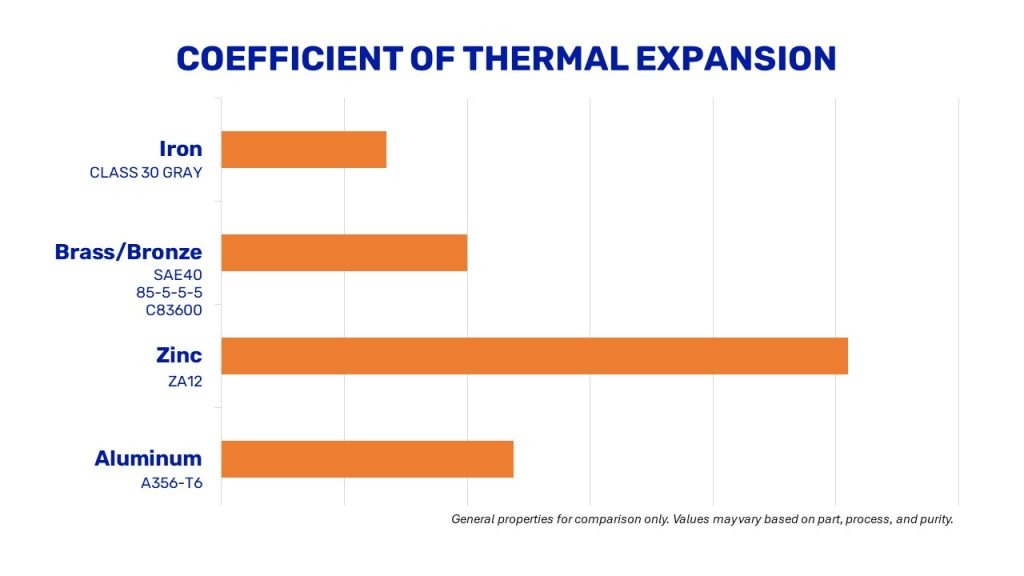

The coefficient of thermal expansion of A356 aluminum with a T6 heat treatment is typically 0.0000119 per °F from 68 to 212°F and 0.0000129 per °F from 68 to 575°F.

A356-T6 CTE is much lower than zinc ZA12. A356-T6 coefficient of thermal expansion is only slightly higher than brass SAE40 and bronze 85-5-5-5 (C83600), but significantly higher than class 30 gray iron.

In industries where parts are subject to wide temperature ranges, such as aerospace, a low CTE helps the part maintain dimensional accuracy and structural integrity. In some applications, it’s important the material CTE matches the expansion properties of the components its assembled with.

In mechanical properties, zinc ZA12 tops the charts when it comes to tensile strength and yield strength, followed by aluminum A356-T6. But, class 30 gray iron’s Brinell hardness outshines other alloys. Brass and bronze are known for their high elongation percentage, followed by aluminum.

When it comes to physical properties, aluminum A356-T6 has the highest electrical conductivity and thermal conductivity, while zinc has the highest coefficient of thermal expansion. Aluminum A356-T6 has the lowest density, followed by zinc, iron, and brass/bronze.

Again, it’s important to note that these are general properties meant for comparing class 30 gray iron, SAE40, 85-5-5-5, C83600, ZA12, and A356-T6. The exact values may vary based on part, process, and purity.

Batesville Products casts zinc ZA12 and ZA5 and aluminum A356 with and without T5 or T6 heat treat. Contact us today to learn more.