Aluminum castings are made by pouring molten metal into a custom mold. When the casting comes out, sometimes we just trim the gates off and the part is ready to go. But sometimes, the casting goes through secondary operations to meet the final specs. These operations might include machining, heat treat, sand core removal, polishing, powder coating, or anodizing.

Let’s talk secondary machining.

Sometimes castings go through secondary machining operation to…

Some features can be cast-in, such as sand core channels, pull core holes, or threaded steel inserts.

Some features may need to be added in secondary machining such as drilling, tapping, threading, and other key features for assembly.

Casting designs require draft, radii, and a certain wall thickness. But if your final assembly requires a 90-degree corner, zero draft, or drastic wall thickness changes, these features can be achieved during the machining process.

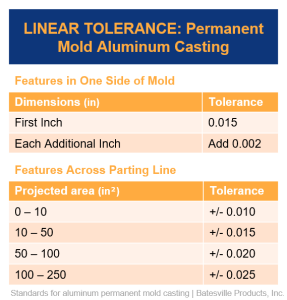

Sometimes castings go though a machining operation to achieve tighter tolerances than the casting process is capable of. Be sure to call out critical specs on your print that could be achieved by casting or machining.

Permanent mold casting tolerances are twice as tight as sand casting.

Machined castings can hold 0.0005 inch tolerances.

If you machine a casting, consider…

Will you use a one-stop supplier like Batesville Products for casting and machining operations, or will you source separate foundries and machine shops?

What’s the best way to fixture this part in the CNC machine? Fixtures are often included in the tooling cost.

During the machining process, aluminum castings may release tension or warp if not fixtured properly. For the best results, you want to load flat castings with minimal flash into the CNC machine.

Consider using flatness gauges, profile gauges, go-no-go gauges, and other inspection tools to verify critical specs before/after machining.

Raw aluminum castings are flexible, which can work to your advantage or disadvantage during machining.

Machining ease depends on the aluminum alloy casted. Some aluminum alloys are almost always heat treated before machining, otherwise they are too soft for precise machining. For permanent mold casting, we only use A356.

A356 castings can be machined with or without heat treat. A356 castings without a heat treat are more flexible than those T6 heat treated. T6 heat treat ages the part and makes it stronger and more rigid.

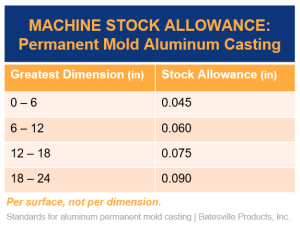

If machining, you will need to add a small machine stock allowance to your casting design.

What’s the best manufacturing method for your design? Casting with secondary machining, or machining from billet?

Learn more about the pros, cons, and when to choose each manufacturing method here.

Call or email us today! We’ve been aluminum casting and machining custom components for over 75 years!