Two popular metal casting methods are sand casting and permanent mold casting. While both manufacturing processes can produce high-quality castings, they differ in several key ways.

Know which manufacturing method is best for your product! Here are the differences between sand casting and permanent mold casting.

Sand casting molds are one-time use, made by mixing sand and a binder. Metal is static poured into the mold, solidifies, then the mold is broken to remove the casting.

Within sand casting, there are 4 types of processes: green sand, nobake, coldbox, and shell.

Permanent mold casting uses a reusable steel mold. Most castings are tilt poured, which is a gravity-fed, machine-controlled method of filling the mold.

Sand Casting Pros

Sand Casting Cons

Permanent Mold Pros

Permanent Mold Cons

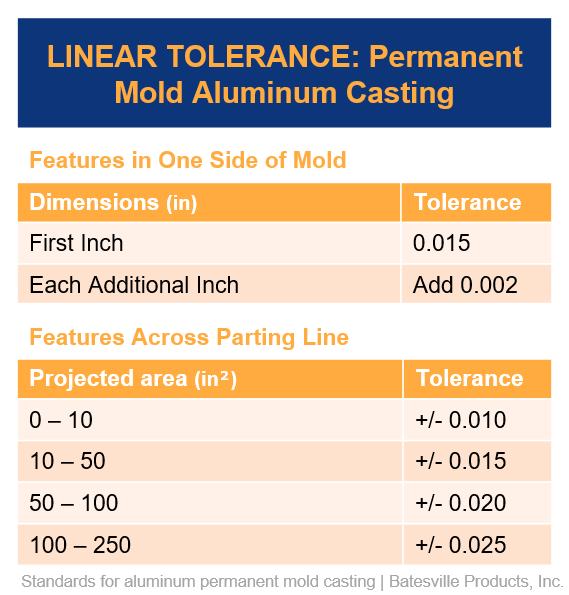

Permanent mold castings hold tighter tolerances than sand castings. Here are some design guidelines for sand casting and permanent mold casting.

Aluminum permanent mold linear tolerances for features on the same side of the mold are 0.015 for the first inch. Add 0.002 for each additional inch.

Aluminum sand casting linear tolerances for features on the same side of the mold are 0.030 for the first inch. Add 0.002 for each additional inch.

The aluminum permanent mold concentricity tolerance for features on the same side of the mold starts at 0.025 inches for a diameter up to 5 inches. For each additional inch, add 0.003 to the tolerance.

The aluminum sand casting concentricity tolerance for features on the same side of the mold starts at 0.050 inches for a diameter up to 5 inches. For each additional inch, add 0.005 to the tolerance.

The average as-cast permanent mold casting surface finish is 200 to 420 RMS. The lower the number, the smoother the surface.

The average as-cast sand casting surface finish is 300 to 560 RMS for nonferrous. 560 to 900 RMS for ferrous green sand.

Permanent mold casting surface finish is generally smoother than sand casting. For an even smoother surface, consider polishing. Make sure your castings are low-porosity before polishing. Otherwise, you may reveal defects when you break the surface.

For more casting design guidelines, check out our 2024 design guide.

When it comes down to making a decision, look at your EAU and quality standards to determine which manufacturing method will give you the best ROI.

Sand casting tooling is relatively low-cost, making it the ideal choice for low-volume production runs (less than 500 pieces a year) and even prototyping.

Permanent mold casting has a moderate tooling cost (between sand and die casting), making it the ideal choice for moderate-volume production (a couple thousand).

Die casting is on the opposite end of the spectrum, with typically the highest tooling cost. It’s quick pressure-fed process is reserved for high-volume production (tens or hundreds of thousands), such as automotive castings.

Permanent mold casting is a high-precision method that can produce complex parts with consistent quality and accuracy. Permanent mold has a better surface finish and lower porosity than sand casting, which eases secondary operations like machining or powder coating.

Low porosity is ideal for pressure-tight vessels, medical equipment, and food equipment.

Still not sure which manufacturing method is best for your product? We’re happy to point you in the right direction!