Each casting method requires its own unique mold. The custom molds used to manufacture metal castings are typically referred to as tooling. The tooling includes the mold cavity, gating, feeding and ejection systems.

Sand casting molds are often made of compacted sand and resin. The molds are relatively low-cost ($6,000 to $20,000) and have quick lead times.

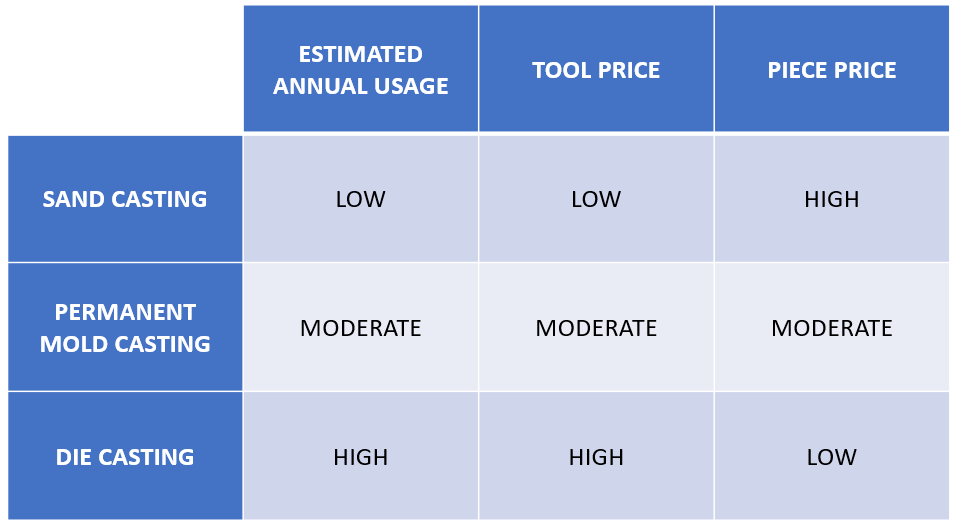

Sand molds are single use. Therefore, sand casting is ideal for low-volume production or even prototyping. Automated casting systems can be added to the tooling for higher volume sand casting.

The castings have a courser surface finish and lower complexity or accuracy than their permanent mold counterparts.

Because of it’s quick and low-cost entry, many companies begin with sand castings, but move on to other methods for large-scale production as their operation grows.

A permanent mold is made by cutting and building cavities, gates, risers, chills, and ejectors into steel. Permanent molds are reusable, gravity-fed molds. The molds can last around 60,000 parts, depending on part design, frequency of use, maintenance, and product standards.

The permanent mold is an investment, typically between $10,000 and $90,000. They are more expensive than sand casting molds due to material and complexity, but less expensive than die casting molds. With the higher price, you achieve tighter tolerances, better as-cast surface finishes, and less porosity.

For permanent mold, you see the best return on investment with moderate volume production. The cost of switching from sand casting to permanent mold with moderate volume production balances out because while the mold price is higher, the piece price is lower and the quality improvements are priceless.

Poorly maintained molds produce more faulty parts, which can increase piece price or disrupt long-term projects.

Our tooling department maintains molds by…

Die casting is similar to permanent mold because both have great as-cast surface finishes and use a reusable steel mold. However, die casting molds use pressure systems (instead of gravity) to inject molten metal.

Die casting molds are great for high-volume production, but have the highest tooling costs ($60,000 to $500,000). This high cost is due to a more complex tool. The complex tooling also takes longer to build, creating longer lead times.

Die casting molds are common in automotive part production and other high-volume industries. These molds typically last around 100,000 parts.

Because of its rapid pressurized injection system, die castings can handle thinner walls than other castings, but can also result in internal porosity. This porosity can cause issues during machining and finishing, especially highlighting flaws in powder coating.

Sand cast tooling

Permanent mold tooling

Die cast tooling