Manufacturing lamp posts or streetlights? Many lighting equipment companies trust aluminum permanent mold casting to supply high-quality components.

Aluminum is known for its durability, which is especially important in outdoor lighting equipment. Aluminum castings are naturally rust-resistant and reliable, offering a long lifespan for lighting fixtures.

Low-porosity aluminum permanent mold castings protect internal wiring and electronics from the outside elements.

For example, this outdoor light post housing is not just decorative, but also protective.

Permanent mold castings have a smoother as-cast surface finish than sand castings. And for street lamps that everyone sees around town, that smooth finish really matters.

Smooth aluminum permanent mold castings are easily powder coated or anodized to further enhance aesthetics.

For example, the light post housing is coated black. When assembled, you get beautiful lamps lining the city streets.

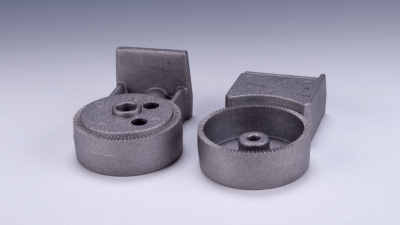

Permanent mold is a great way to manufacture complex, precise parts. You can achieve intricate designs with tight tolerances. Permanent mold castings are also consistent and repeatable for moderate volume production.

For example, this parking lot lighting mechanism has interlocking teeth. To function properly, these teeth must be uniform and precise from part to part.

Aluminum has great thermal conductivity. If overheating of lighting and electrical equipment is a concern, choose aluminum casting.

Request a quote for custom lighting equipment castings!