Have you ever watched someone polish aluminum and zinc castings? A lot more goes into it than most people think! In this article, we will take a deep dive into metal polishing – from selecting a surface finish to tools and equipment.

Learn more by watching this recording of recent webinar with Danny Courter, BPI Polishing Lead with over 40 years of metal polishing experience.

Metal polishing creates a smooth, consistent surface. There are many reasons customers might want their castings polished.

The level of surface finish is chosen by the customer, often determined by the part’s end application. Metal polishers use a combination of tools and series of operations to achieve the finish requested by the customer. Finishes we achieve at BPI include…

It takes multiple steps to achieve these surface finishes. Polishers use multiple tools in a series of operations.

Sometimes, one part will have multiple surface finishes. For example, the A surface of a casting might be visible in assembly and require a 400-grit finish, while the B surface might be hidden and doesn’t require polishing at all. This is common in electrical housings or other casings.

It is important to note that there is a difference between polishing and grinding. The goal of polishing is to remove as little of material possible, to hold the original contour of the casting. Grinding involves removing a large amount of material. Grinding might be performed to remove excess material or correct defects.

Polishers use different tools to achieve different surface finishes. Perhaps two of the most common polishing tools are the polishing jacks and dual action sanders.

Polishing jacks are wheels with interchangeable grit belts. A dual action sander is a hand tool that is mainly used as a final operation. It has random and orbital settings to create an A1 finish. Often, these tools are used together. For example, the operator might start with the polishing jacks then complete the part with the DA sander.

Metal polishing is traditionally a highly skilled art. The operator must use a variety of tools, apply even pressure, and balance perfection with efficiency to create an even surface finish. This type of finesse only comes with experience.

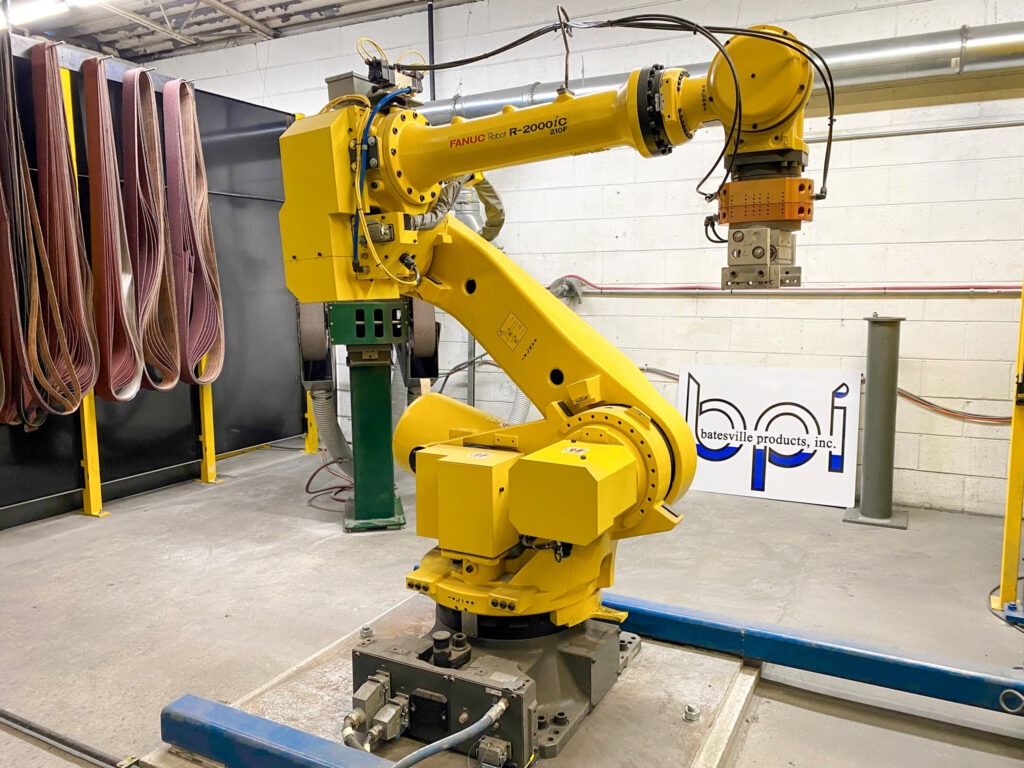

Today, advances in equipment and technology have turned this artform into a science. The polishing robot efficiently polishes parts by applying even pressure. It improves quality and consistency standards by ensuring that the same exact area is polished on each casting.

The robot essentially replaces polishing jack operations. After a part comes off the robot, we sometimes use the DA sander to finish the job.

It can be daunting to decide the final look of your new product. Therefore, we often send samples of different finishes for customers to choose from.

When deciding what surface finish your new product should have, consider the following:

Does the look, texture, or durability of the product matter? For example, medical products often have different surface requirements than valves or hinges.

Maybe you manufacture food equipment, and it is highly important that the surface is evenly textured.

Or maybe you produce safety equipment, where it is important that the product is easily accessible and identifiable. In this case, you might want to consider polishing and power coating your product neon yellow.

If the product is hidden in final assembly, maybe you can cut costs by removing polishing operations. On the flip side, it is important to make highly visible castings, such as these decorative architecture corners, aesthetically pleasing.

If your company color is cherry red, polishing then powder coating your product will make it stand out from the competition!

Check out our casting gallery to see more surface finish examples!