Investment casting is a metal casting process that uses a wax pattern to create intricate parts with high dimensional accuracy and a smooth surface finish.

Investment casting, also known as precision casting or lost-wax casting, is a metal casting process that uses a wax pattern. The wax pattern is coated with a ceramic shell, then melted away. Metal is poured into the shell cavity. This process is known to create intricate parts with high dimensional accuracy and a smooth surface finish.

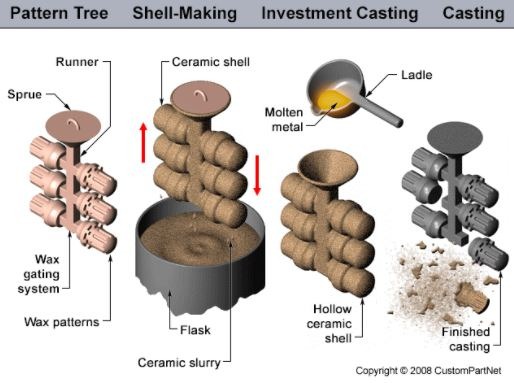

First, you create a wax pattern. This pattern is an exact replica of your design/final part. You must create a wax pattern for every part you wish to produce.

Then, the wax patterns are assembled onto a “tree.” The tree has a center wax sprue connecting all the parts. By making a tree, you can cast multiple parts simultaneously.

Next, the wax tree is dipped into ceramic material, coating the wax in a shell. The ceramic shell is dipped and coated in layers, building a thick shell.

Once the ceramic shell has dried and hardened, it’s heated. The wax melts out of the tree, leaving an empty cavity for the metal. Metal is poured into the cavities, taking on the shape of the original wax patterns. Once the metal solidifies, the ceramic shell is broken away, revealing the metal casting!

Castings are then removed from the sprue and can undergo secondary operations such as machining, heat treat, and polishing.

Permanent mold casting is a gravity-fed metal casting process that uses a reusable steel mold.

First, you design and build a reusable steel tool. This tool is complete with a cope, drag, gates, risers, chills, and ejectors.

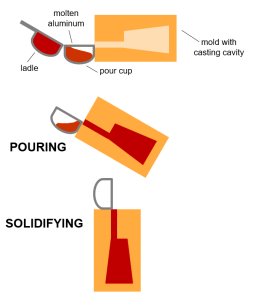

When it’s time to pour, the mold is mounted onto a programmed tilt-pour press. The mold is preheated and sprayed with a coating. Coatings help with temperature, ejection, and mold life.

To create a casting, molten metal is poured into the pour cup. Then, the tilt pour press tilts back at a pre-programmed rate. As it tilts, metal is gravity-fed into the gating and mold cavity. Within minutes, the casting solidifies. Then, the press returns to its upright position and opens the cope and drag. The casting is ejected and ready for secondary operations such as trimming, machining, or polishing! The mold is ready for more metal to be poured, so the cycle continues.

Here are the major differences between investment casting and permanent mold casting.

While permanent molds are made of reusable steel, investment casting uses disposable ceramic and wax. A new mold must be created for each part in investment casting.

Overall, the multi-step casting process is more complex for investment casting than permanent mold, mainly due to the differences in molds.

While both casting processes are known for precision, investment casting as-cast tolerances and accuracy are slightly finer than permanent mold. This makes investment casting ideal for small, very detailed and intricate parts. As-cast surface finish for investment casting is 60 to 200 RMS, smoother than the 200 to 400 RMS surface finish of permanent mold.

In terms of dimensional accuracy and as-cast surface finish, both investment casting and permanent mold excel over sand casting.

Both processes can undergo secondaries such as heat treating, machining, or polishing, which offset differences in tolerances and surface finish.

Investment casting tooling is often more expensive than permanent mold due to complex wax pattern creation, disposable ceramic molds, and additional steps in the process. This makes investment casting ideal for smaller production runs where intricate details are essential, such as jewelry or aerospace components.

For the best ROI on a reusable steel mold, permanent mold casting is ideal for moderate volume production, which is common in medical, food and beverage, and electrical/lighting industries.