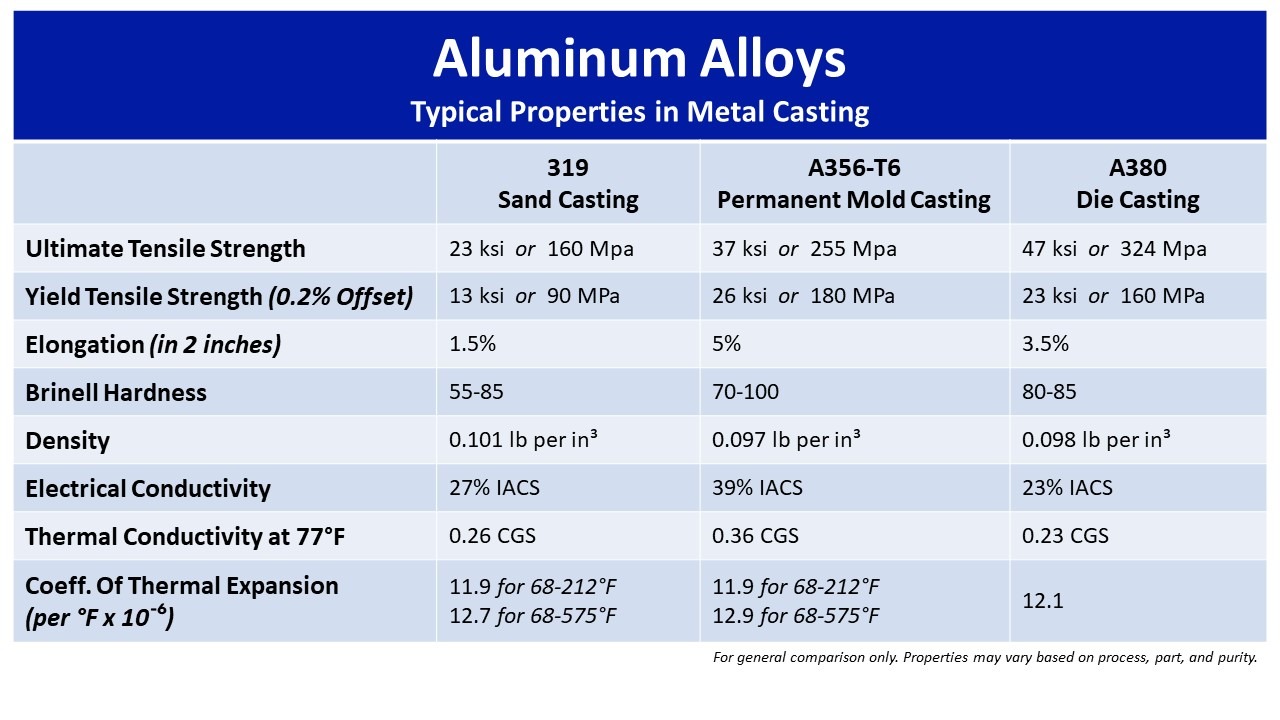

These three aluminum alloys are very similar, but used in different metal casting processes.

Let’s compare and contrast the typical mechanical and physical properties of these common aluminum casting alloys.

Note: These are general figures meant for comparison. Values may vary based on part, process, and purity.

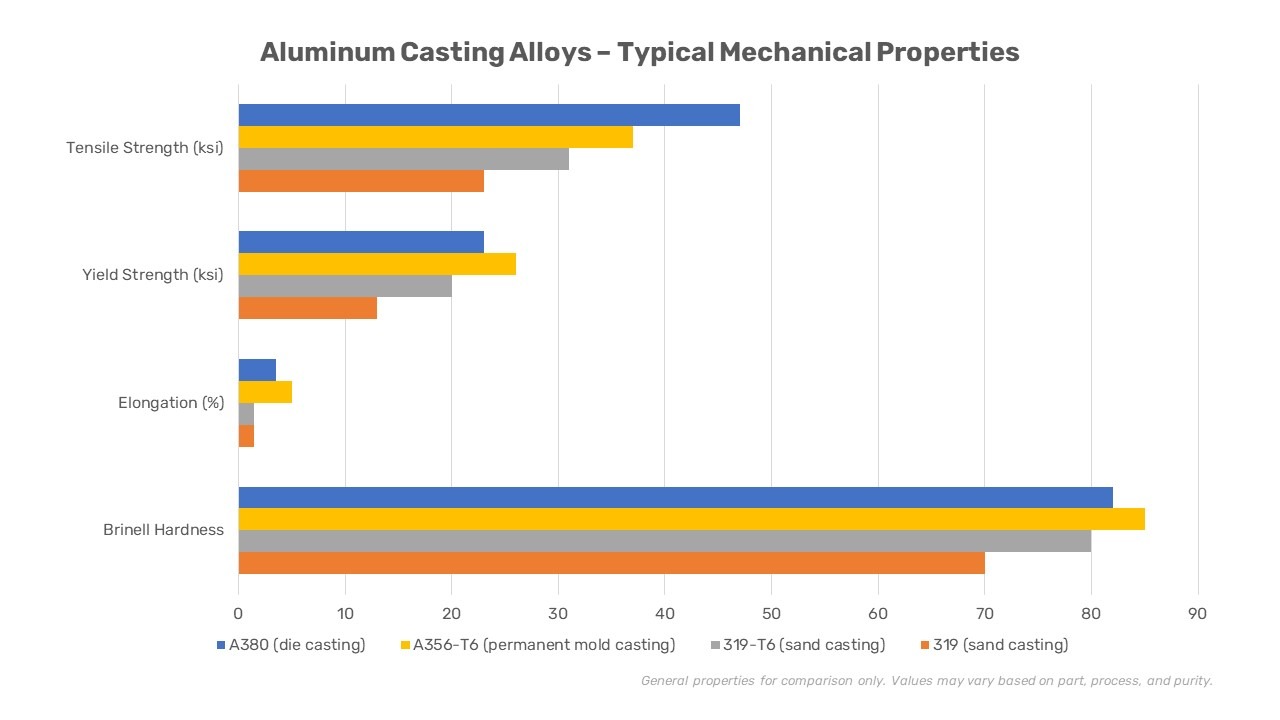

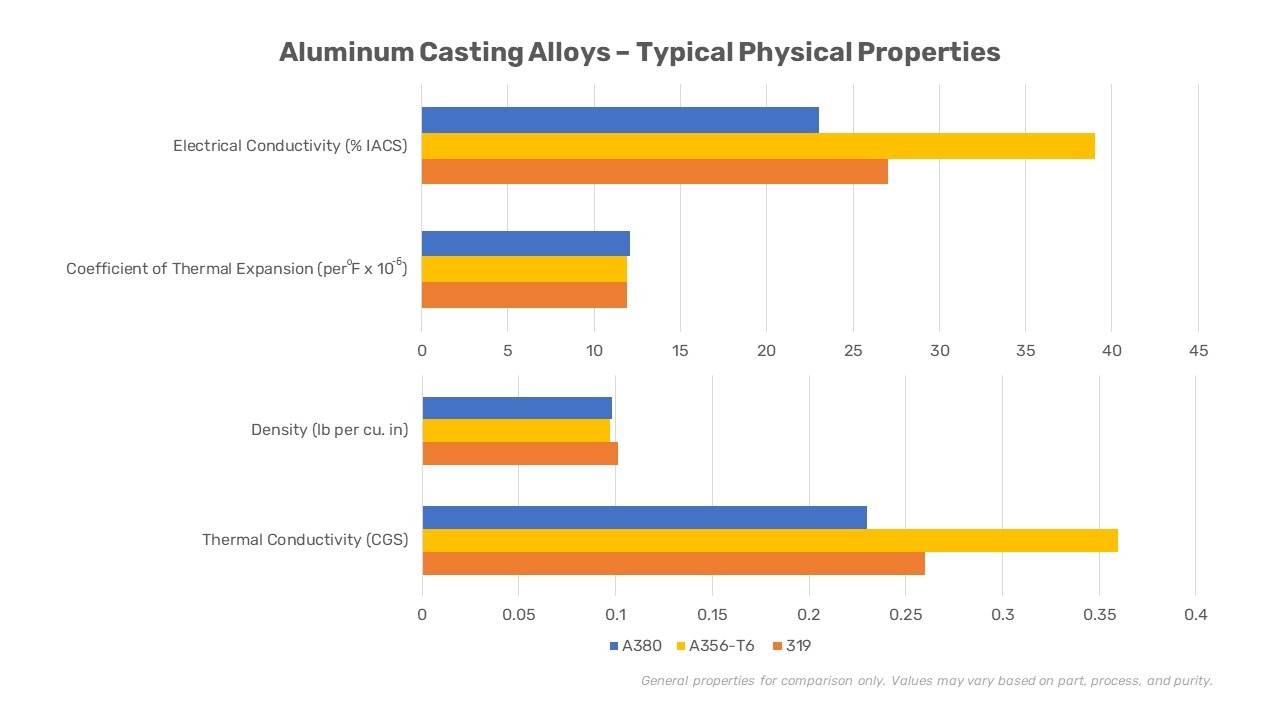

Permanent mold A356-T6 outshines the sand and die casting aluminum alloys in

It outshines sand casting (319 and 319-T6) in tensile strength.

It’s ever so slightly lower than the others in terms of density and thermal expansion.

Aluminum 319 Sand Casting

The tensile strength of a 319 aluminum casting is typically 23 ksi (160 MPa) in sand casting.

Aluminum 319-T5 Sand Casting

The tensile strength of a 319 aluminum casting with a T5 heat treatment is typically 25 ksi (170 MPa) in sand casting.

Aluminum 319-T6 Sand Casting

The tensile strength of a 319 aluminum casting with a T6 heat treatment is typically 31 ksi (215 MPa)

Aluminum A356-T6 Permanent Mold Casting

The tensile strength of an A356 aluminum casting with a T6 heat treatment is typically 37 ksi (255 MPa) in permanent mold casting.

Aluminum A380 Die Casting

The tensile strength of an A380 aluminum casting is typically 47 ksi (324 MPa) in die casting.

The yield strength is measured using the 0.2% offset method.

Aluminum 319 Sand Casting

The yield strength of a 319 aluminum casting is typically 13 ksi (90 MPa) in sand casting.

Aluminum 319-T6 Sand Casting

The yield strength of a 319 aluminum casting with a T6 heat treatment is typically 20 ksi (140 MPa) in sand casting.

Aluminum A356-T6 Permanent Mold Casting

The yield strength of an A356 aluminum casting with a T6 heat treatment is typically 26 ksi (180 MPa) in permanent mold casting.

Aluminum A380 Die Casting

The yield strength of an A380 aluminum casting is typically 23 ksi (160 MPa) in die casting.

Elongation is measured over 2 inches (or 4 times diameter).

Aluminum 319 Sand Casting

The elongation of a 319 or 319-T6 aluminum casting is typically 1.5% in sand casting.

Aluminum A356-T6 Permanent Mold Casting

The elongation of an A356 aluminum casting with a T6 heat treatment is typically 5% in permanent mold casting.

Aluminum A380 Die Casting

The elongation of an A380 aluminum casting is typically 3.5% in die casting.

Brinell Hardness is measured with a 500-kgf load and a 10-mm ball.

Aluminum 319 Sand Casting

The Brinell Hardness of a 319 aluminum casting is typically 55-85 in sand casting.

Aluminum 319-T5 or 319-T6 Sand Casting

The Brinell Hardness of a 319 aluminum casting with a T5 or T6 heat treatment is typically 65-95 in sand casting.

Aluminum A356-T6 Permanent Mold Casting

The Brinell hardness of an A356 aluminum casting with a T6 heat treatment is typically 70-100 in permanent mold casting.

Aluminum A380 Die Casting

The Brinell Hardness of an A380 aluminum casting is typically 80-85 in die casting.

The density of a casting will vary depending on the casting process, foundry practices, and part requirements.

Aluminum 319 Sand Casting Alloy

The density of 319 aluminum is typically 0.101 pounds per cubic inch.

Aluminum A356-T6 Permanent Mold Casting Alloy

The density of A356 aluminum with a T6 heat treatment is typically 0.097 pounds per cubic inch.

Aluminum A380 Die Casting Alloy

The density of A380 aluminum is typically 0.098 pounds per cubic inch.

Aluminum 319 Sand Casting Alloy

The electrical conductivity of 319 aluminum is typically 27% IACS.

Aluminum A356-T6 Permanent Mold Casting Alloy

The electrical conductivity of A356 aluminum with a T6 heat treatment is typically 39% IACS.

Aluminum A380 Die Casting Alloy

The electrical conductivity of A380 aluminum is typically 23% IACS.

Aluminum 319 Sand Casting Alloy

The thermal conductivity of 319 aluminum is typically 0.26 CGS at 77 degrees Fahrenheit.

Aluminum A356-T6 Permanent Mold Casting Alloy

The thermal conductivity of A356 aluminum with a T6 heat treatment is typically 0.36 CGS at 77 degrees Fahrenheit.

Aluminum A380 Die Casting Alloy

The thermal conductivity of A380 aluminum is typically 0.23 CGS at 77 degrees Fahrenheit.

Aluminum 319 Sand Casting Alloy

The coefficient of thermal expansion of 319 aluminum is typically 0.0000119 per °F from 68 to 212°F and 0.0000127 per °F from 68 to 575°F.

Aluminum A356-T6 Permanent Mold Casting Alloy

The coefficient of thermal expansion of A356 aluminum with a T6 heat treatment is typically 0.0000119 per °F from 68 to 212°F and 0.0000129 per °F from 68 to 575°F.

Aluminum A380 Die Casting Alloy

The coefficient of thermal expansion of A380 is typically 0.0000121 per °F.

Aluminum 319 Sand Casting Alloy

Aluminum A356-T6 Permanent Mold Casting Alloy

Aluminum A380 Die Casting Alloy