Prototyping can save you time, money, and headaches prior to production by ensuring your design is the best it can be. While the prototype isn’t a perfect replica of the final manufactured product, it is a great way to quickly achieve a hands-on copy of your design.

Therefore, it is sometimes beneficial to prototype a casting before starting foundry production. Today, we will walk through 6 rapid prototyping methods for aluminum and zinc castings.

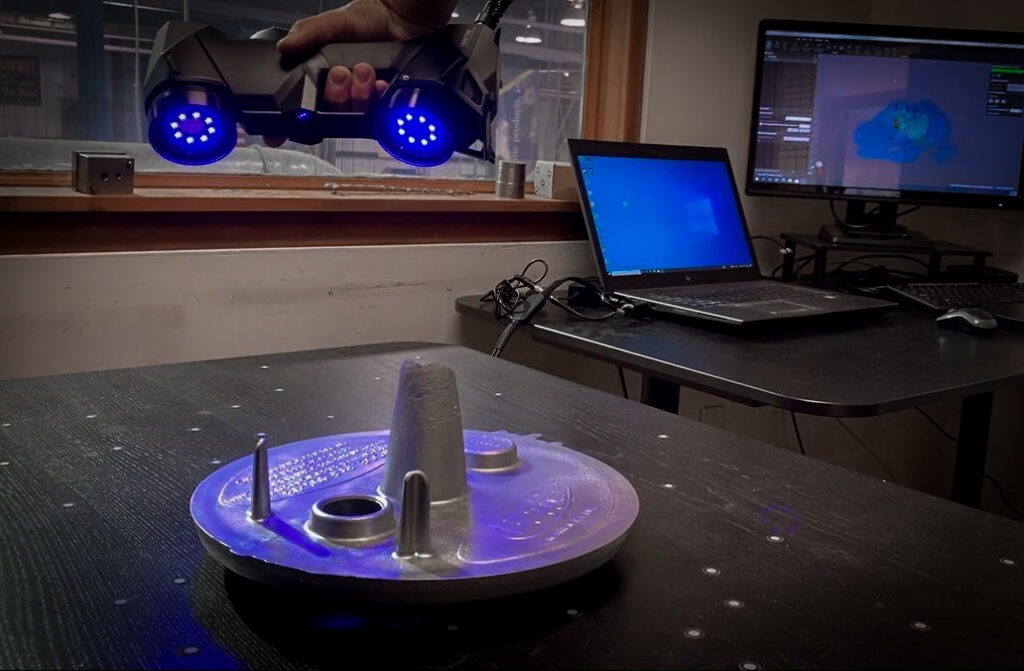

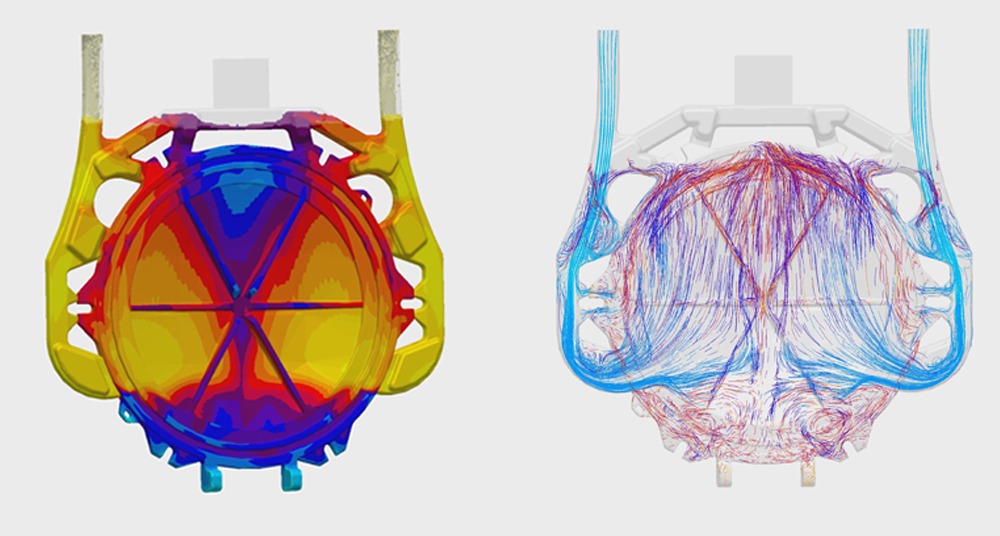

If you have a current product and are interested in switching your manufacturing method, consider virtual prototyping. At Batesville Products, our engineers create virtual prototypes of each project. Parts are brought to life in design software by 3D scanning.

These virtual three-dimensional models are put through a Finite Element Analysis (FEA). This analysis will simulate permanent mold casting by showing how the metal will flow and solidify in the mold, predicting porosity and weakness. This creates the opportunity to make design improvements before the permanent mold is created or any parts are physically poured. Therefore saving time and money in the production process.

Sand casting is a common prototyping method for permanent mold and die casting. While it is low-cost and gives a comparable picture of the structural design of your permanent mold or die casting, it is not a perfect imitation.

The dimensional integrity, porosity, and surface finish will not be comparable. Therefore, you shouldn’t plan to pressure test or thoroughly inspect prototypes because the final product will be created in a process with different dimensional, porosity, or surface finish standards.

Sand-cast prototypes are often preferred over plaster mold prototypes unless your product has super thin walls. The plaster mold process is beneficial for providing a good surface finish, inexpensive tooling, and design flexibility. However, part costs are often higher.

This prototyping method is less common, as it has longer lead times and is most cost effective in higher volume.

However, investment casting creates quality prototypes comparable to your final product.

3D printing is an innovative prototyping method that is becoming more available and cost-effective in the industry. Printers create a three-dimensional model of your part by layering materials (often plastic).

3D printing is a quick and low-cost option, but it has size and material restrictions. For example, a 3D printed plastic model of an aluminum part involved in heat dissipation will not allow you to test how the part will perform in transferring heat.

NOTE: If you are prototyping to test mechanical properties rather than just “fit,” is important that your prototype is comparable to the finished product and subject to real-life tests of its end application. If you can closely simulate the finished product, you will not be subject to unpleasant surprises post-production.

Hogging out refers to machining a piece of solid metal into your desired part.

Hogging out is a quick and precise prototyping method. However, the programming and material removal is relatively expensive, and the process is not effective in simulating mechanical properties such as draft, fillets, and radii.

Prototyping has many benefits. It is cheaper than cutting a permanent mold, especially if there is a potential for design changes after prototyping. It also provides a quick, no commitment, hands-on example of your product. This is great for judging form and fit, but is not a perfect example of your part.