This customer is in the medical industry, producing adaptive equipment for people with disabilities. BPI manufactures colorful handlebars for a variety of child-sized rehabilitation walkers.

This customer needed a part that not only looked good but that the child could safely rely on.

The customer chose an aluminum permanent mold casting because it is lightweight, yet strong.

The handlebar is sturdy enough to bear the weight of the person using it to walk and the fully assembled walker is easily transportable.

Since this casting assembles onto the walker in three different locations, it is important that it hits tight tolerances to ensure a perfect fit.

The same high-quality part must also be replicated into a variety of sizes to build a complete product line. The customer creates walkers for customers of all ages, so we cast smaller and larger versions of the product with the same proportions.

The finish is one of the most important operations of this casting.

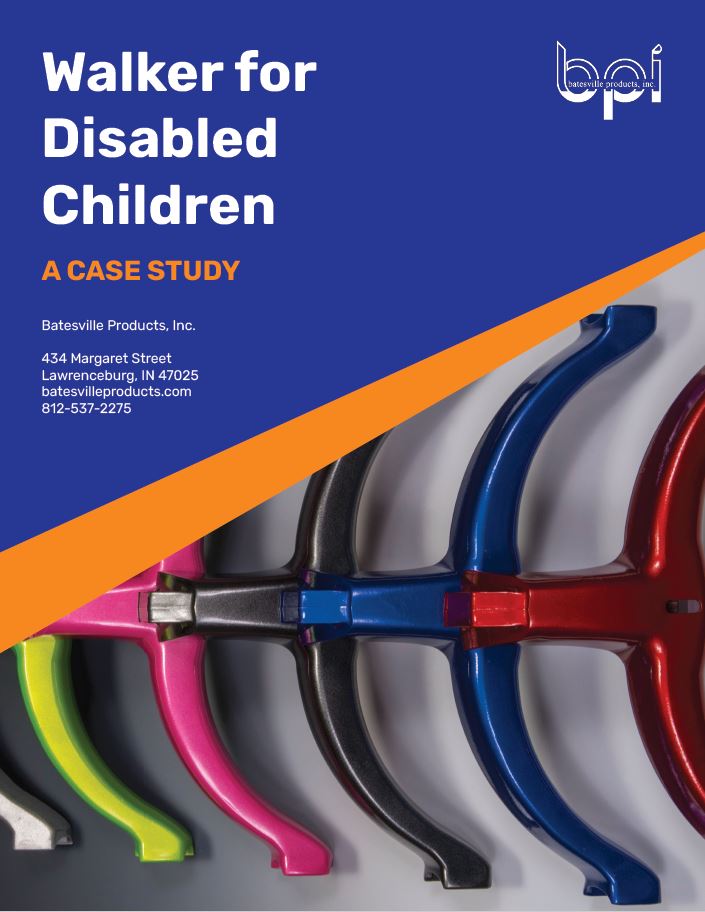

Since this casting sits directly in front of the child, the highly-visible product must look great! The part is powder coated in a variety of bright candy colors (including green, pink, blue, and red).

The child can choose a fun, cheerful color for the walker they will use every day!

You can tell this customer is all about helping others.

The impact this product has on the lives of others makes it one of our favorite projects to work on. In fact, we still manufacture this product today. With a variety of sizes and colors to make, it never gets old.

Aluminum castings with low porosity and fine grain structure are ideal for the medical industry.

At Batesville Products, we have experience manufacturing cart bases, heat sinks, pump enclosures, and structural components for MRI machines and scanners.