Shot blasting is a finishing method that produces a consistent, textured surface finish.

First, a casting is fixtured and hung in the shot blast machine. The doors close.

When the machine is turned on, handfuls of small pellets (called “shot”) are thrown (or “blasted”) all around. They hit every surface of the casting.

The impact of the shot on the casting creates a more abrasive finish.

The intensity of the texture is controlled by the shot frequency (25 HZ – 60 HZ) and cycle duration.

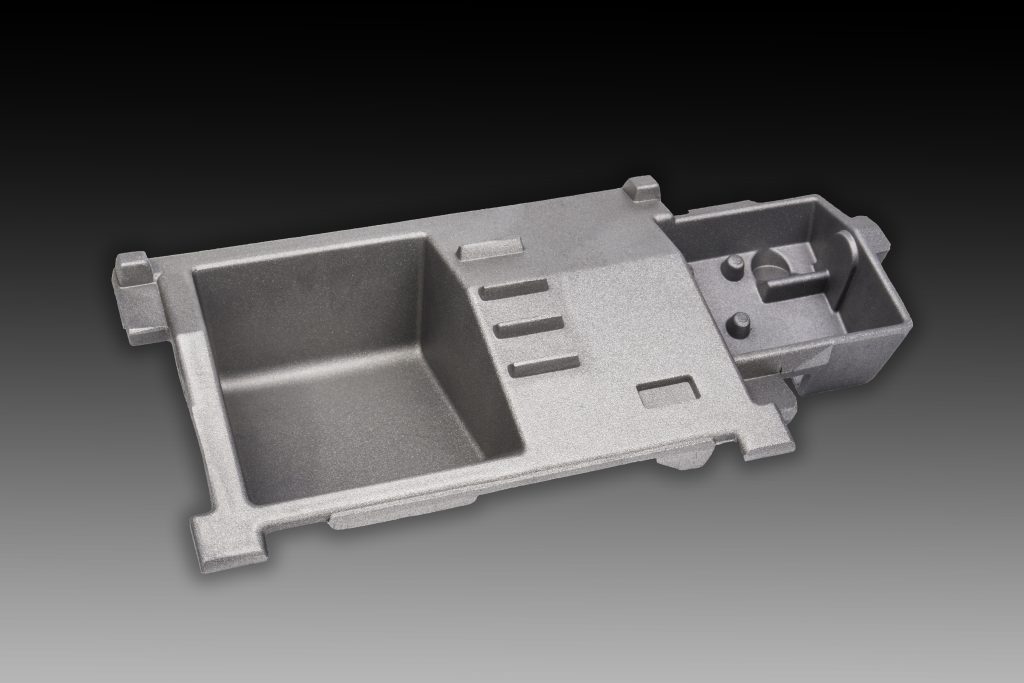

For example, here is a forklift control panel with a shot blasted surface finish.

Shot is another name for pellets of media. Many materials can be used as shot blast media. Examples include stainless steel shot or cut wire.

Powder coating requires a perfectly consistent surface to achieve a high-quality final look. Any defects, burrs, pits, or areas of varying roughness will be highlighted by the powder. Therefore, shot blasting can be used before powder coating to ensure a consistent finish.

Not looking for a shot blasted finish? Alternative casting finishes include: