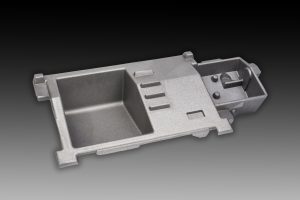

At Batesville Products, we specialize in permanent mold casting, machining, and finishing for industrial equipment and heavy machinery customers. Here’s how we helped a leading forklift manufacturer take their equipment to the next level with a high-quality casting for their control panel.

The customer required a heavy control panel to serve as a counterweight in their forklifts for optimal safety.

Since this panel is right under the nose of the operator, it also needed to have a premium finish, making zinc an obvious choice.

The customer needed a supplier who could produce a product with intricate features that would function in assembly.

Batesville Products is one of the few US suppliers that offers both zinc and aluminum permanent mold casting.

We recommended permanent mold for the customer’s control panel, as it provides better surface finish than sand casting and can achieve intricate features efficiently.

After many years of using zinc for the control panel, the customer decided to switch to aluminum to lower costs and weight. The forklift design evolved so the counterweight of the control panel was no longer needed for safety.

The lightweight aluminum casting didn’t compromise the sleek look of the control panel, or its reliable functionality. Aluminum castings are known for durability, density, and corrosion resistance, making it an ideal choice for heavy machinery.

To match the customer’s line of industrial machinery, we used stainless steel shot blasting for a consistent, textured surface finish. This technique also helped with adhesion and surface evenness for subsequent powder coating.

This part is a perfect example of the pros and cons of aluminum and zinc.

Zinc is ideal for a product that requires weight and a high-quality finish. But when the weight isn’t necessary, aluminum can achieve the same function, but at lower cost when factoring material, labor, and transportation. Often in today’s world, lighter is better!

When we say the product turned out great – we really mean it. We use forklifts from this company in our own manufacturing facility!

Batesville Products has supplied this component for many years, which speaks volumes to customer satisfaction.

This project showcases how Batesville Products helps industrial equipment and heavy machinery customers achieve their desired product outcomes.

Whether it’s choosing the best material, utilizing innovative casting methods, or delivering superior surface finishes, we are committed to providing high-quality and cost-efficient solutions.