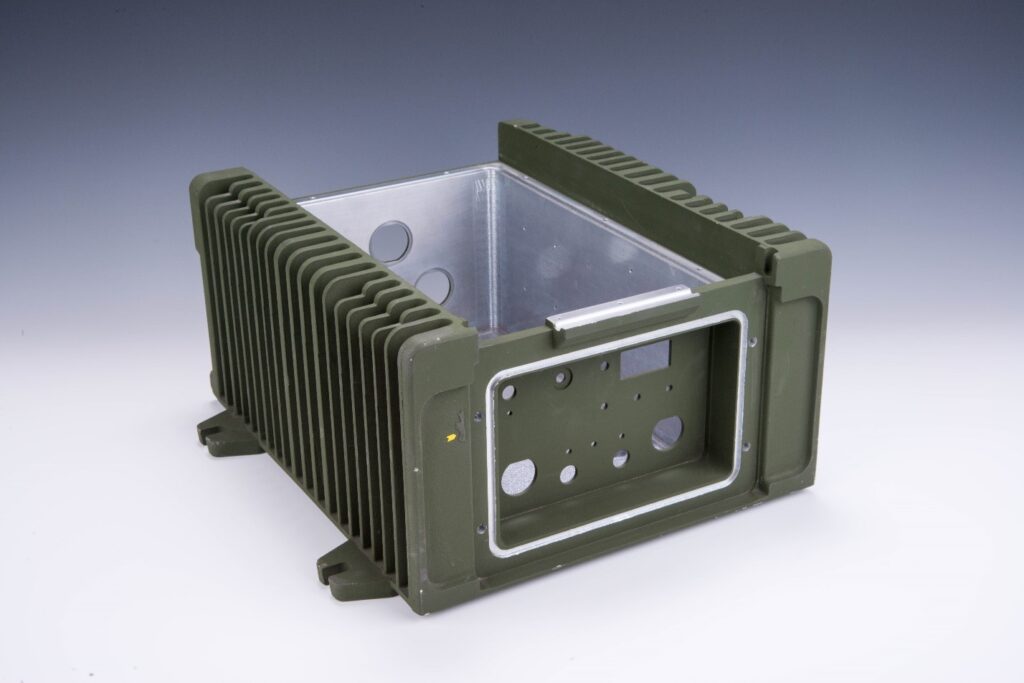

This customer services the military industry with parts such as this tactical power supply housing for the US Army.

The customer needed a supplier who could manufacture a complex, lightweight housing that would meet military product standards.

With almost 75 years of permanent mold experience and having done previous work in the military industry, we confidently partnered with the customer on this complex part.

The casting is unique because it is a six-parted permanent mold casting, making it an extremely complex and uncommon permanent mold process.

After casting and machining, this part received a special coating operation. The part received a chromate coating and chemical agent reactive coating paint that is necessary in the military industry.

These special coatings help the part be environmentally sealed, waterproof, and heat transferrable.

By using an aluminum housing, the customer was able to make the product lightweight, a key selling point in the military industry. The fully assembled power supply weighs 36 pounds.

The customer was pleased with the final look of the part; the army-green finish was not only aesthetic but also practical for the military industry.

Many years later, we still produce parts today for this satisfied customer.