Manufacturing is an ever-evolving industry clouded with negative perceptions. In honor of National Manufacturing Month, let’s bust 8 common manufacturing myths.

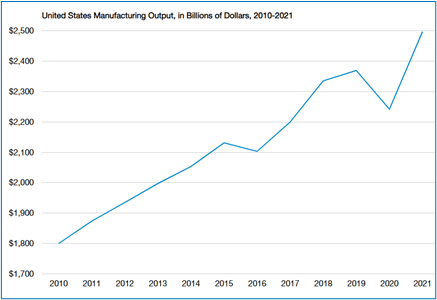

Manufacturing is still a vital part of the US economy. According to the National Association of Manufacturers, US manufacturers account for 10.7% of the total US output with $2.5 trillion.

Specifically in foundries, which supply a variety of manufacturing industries, output has grown about 4% every year in the last five years, and is projected to continue this growth pattern.

While there may be more consolidation, giving the appearance of less manufacturing facilities, those facilities are producing more and more.

Obviously not all, considering we’re still in business 😉

Many well-known and successful brands still manufacture products in the USA.

While offshoring became popular in the 1970s, today we’re seeing a push towards reshoring. Uncertainty with transportation, labor, and the political landscape are major reasons there’s a resurgence in “made in the USA.” Specifically after the events of 2020 revealed how crucial a reliable supply chain is, there’s been a large movement towards domestic manufacturing.

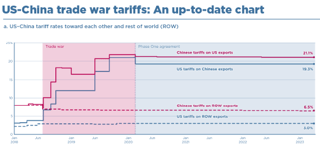

Many companies choose to offshore manufacturing because it is cheaper. Manufacturers outside the US typically have low wages and less labor and environmental regulations, which translates to lower costs. However, offshored products have added costs of transportation and taxes/tariffs as well as implications on quality and supply communication.

Quality

USA manufacturers pride themselves on craftsmanship and quality. American manufacturers have a lot of checks and balances in place to ensure a quality product, best demonstrated by quality control standards like ISO 9001.

Communication

One factor that you can’t put a price on is communication. Domestic manufacturing overcomes language, culture, governmental, and time zone barriers.

Source: Peterson Institute for International Economics

The manufacturing landscape has remarkable transformed over the past decade, marked by significant advancements in technology and innovation. From the widespread implementation of cutting-edge robotics and automation systems to rapid prototyping and 3D printing, manufacturing is at the forefront of technological progress.

These innovations not only enhance productivity but also elevate the quality and precision of manufacturing processes, positioning the industry as a hotspot of technological growth.

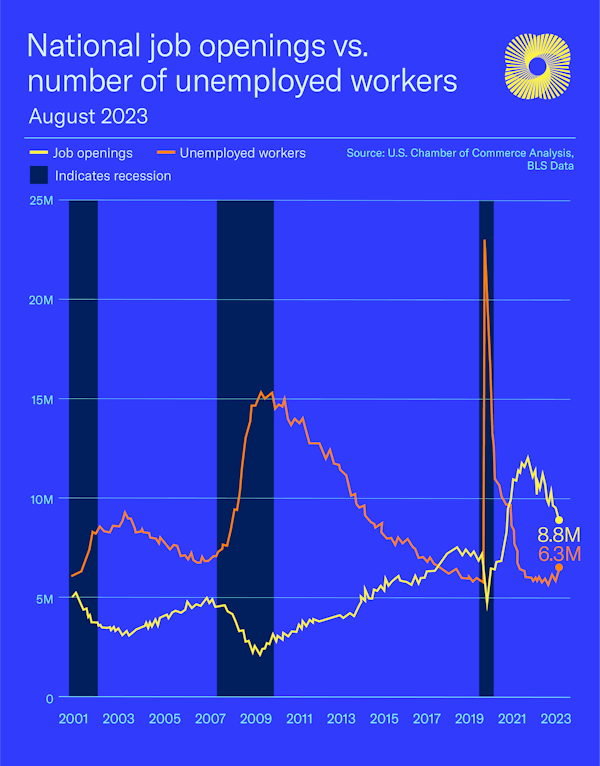

Here’s the hard facts: There are more jobs than people to work them.

The US Chamber of Commerce shows that as of June 2023, there were 9.8 million job openings, but only 5.9 million unemployed workers. This gap is expected to widen as the baby boomer generation retires.

Very few manufacturing facilities are going completely “lights out” and replacing workers with machines. Instead, automation is used to help fill in the gaps. Instead of replacing people, robots are redeploying people.

Marrying automation with traditional craftsmanship creates more appealing, safer jobs. For example, when Batesville Products implemented a robotic saw, it didn’t mean we stopped hiring sawing employees. Instead of replacing the job, the job function changed. Rather than saw by hand, these employees now load and oversee a robot. This lowers the risk of hand injury while also improving consistency.

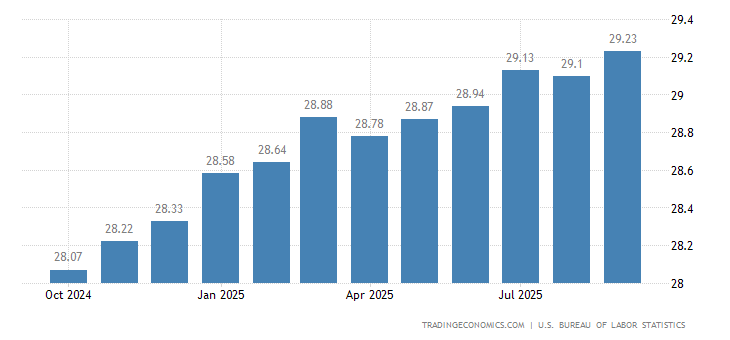

US Manufacturing wages are on a steady incline. According to the US Bureau of Labor Statistics, The United States average hourly wage in manufacturing has increased 5% in the last 12 months.

The technology in modern manufacturing is making jobs even more desirable. Students graduating with an aptitude for technology can come into an entry level position. They’ll work alongside robots and eventually be the ones programming them. Manufacturers have a responsibility to make the community aware of these advanced career opportunities within the industry.

Watch this video for a short story about how technology changes the manufacturing job landscape.

Some, but not all. Lots of people overlook how many steps there are to manufacturing one product. Or in our case, manufacturing one piece of one product.

Custom products require custom solutions. Custom solutions aren’t just a plug-and-play-one-step-process.

For example, imagine the effort and time that goes into just this tiny piece of a medical cart.

First, the engineering team went back and forth designing the blueprint and making it castable. Then tools, sand cores, and fixtures were built. The tool was prepped, metal was poured, and castings were cooled. Sawing. Heat treat. Machining. Inspection. Polishing. Powder coating. Shipping. Several steps and people involved just to make one component of an assembly.

When you think of manufacturing, does a picture of a 1900’s factory pop in your head? This stereotype is NOT accurate.

Lean manufacturing is a hot topic at every leadership table. Environmental regulations alone have evolved over the years to improve the sustainability of manufacturing. Across the industry, there is a push to reduce waste and conserve energy.

Sure you’ll still get a little dirty and sweaty with hard work, but modern manufacturing is all about 6S: sort, straighten, shine, standardize, sustain, and of course, safety. Modern manufacturers strive to create a nurturing environment that employees want to stay in, not a dark and dirty hole in the wall.

Are you surprised? These are just some of the many incorrect stereotypes about the manufacturing industry.

We’re working hard educating the next generation, getting in the community, and collaborating with AFS, NFFS, Conexus Indiana, and other organizations to bust these myths!