Permanent mold aluminum castings are common in the telecom industry. Here’s why.

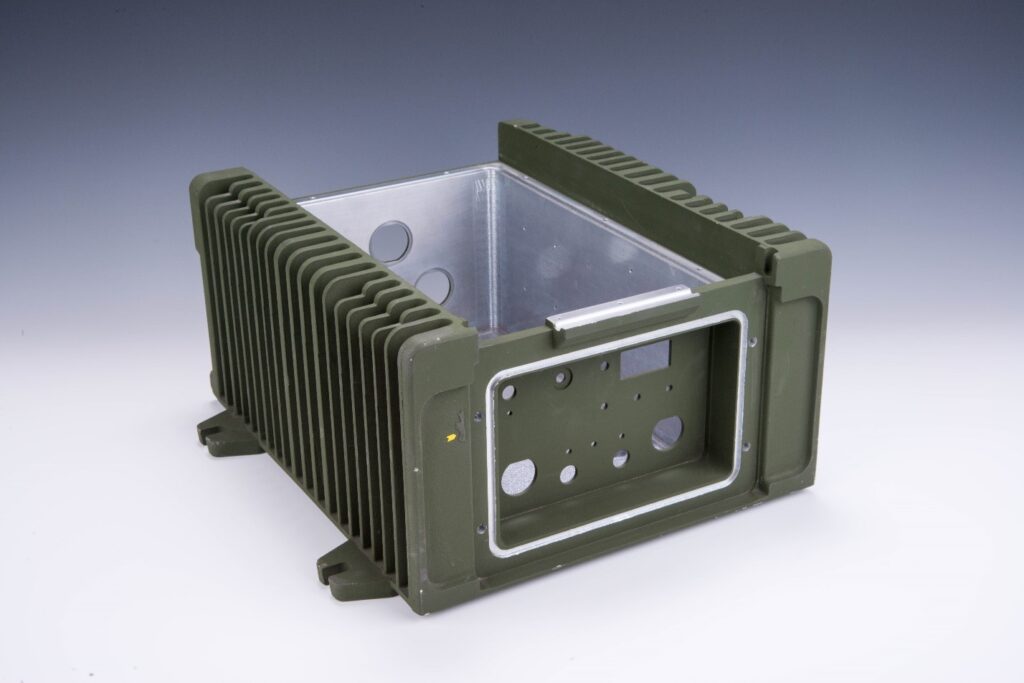

Aluminum conducts heat, which is great news for electrical products! Cast-in ribs, fins, and pins help transfer heat even more.

Here’s a custom power supply housing with special fins and coatings that aid heat transfer.

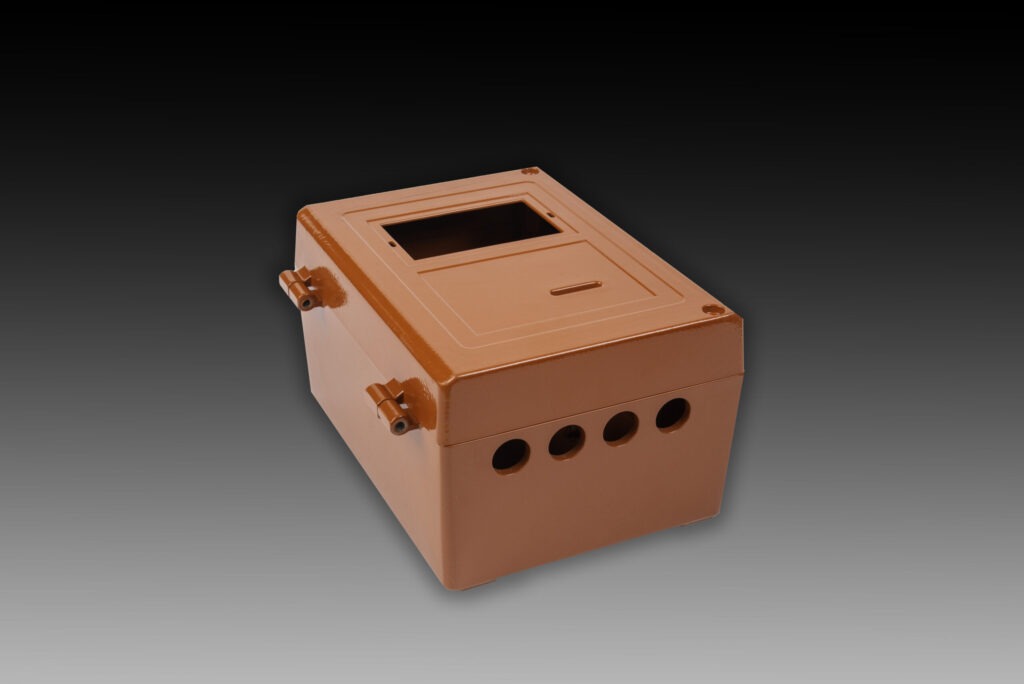

Aluminum is naturally rust-resistant! Unlike steel, when aluminum is exposed to moist air, it becomes stronger! It forms a tough, protective oxide coating that won’t rust.

This enhances the longevity of products in harsh environments, and helps outdoor products protect important interior electronics. Aluminum castings are durable and strong.

Anodizing or powder coating your aluminum castings can further protect your product from any other forms of corrosion.

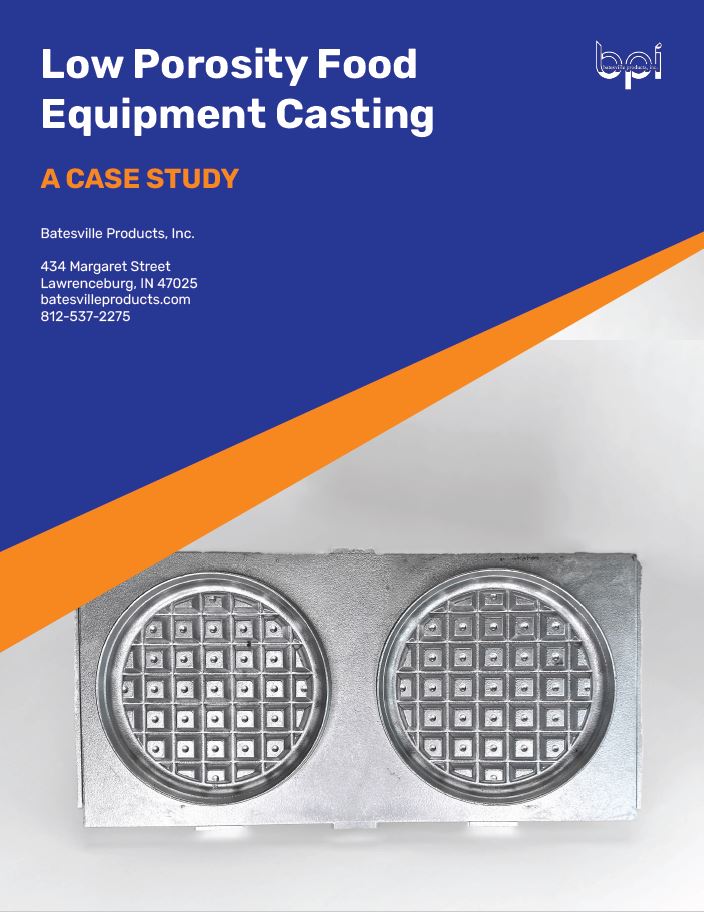

Permanent mold castings are dense with low porosity. So what?

This means they are great at keeping water and other unwanted contaminates out.

Sand castings or die castings tend to have higher porosity than permanent mold castings, making them like a sponge. For example, a customer came to us with a sand casting they used for large-scale waffle production. Because of the porosity, food particles and cleaners were seeping into the machinery, impacting sanitation and equipment longevity. Low porosity permanent mold castings helped solve leakage problems!

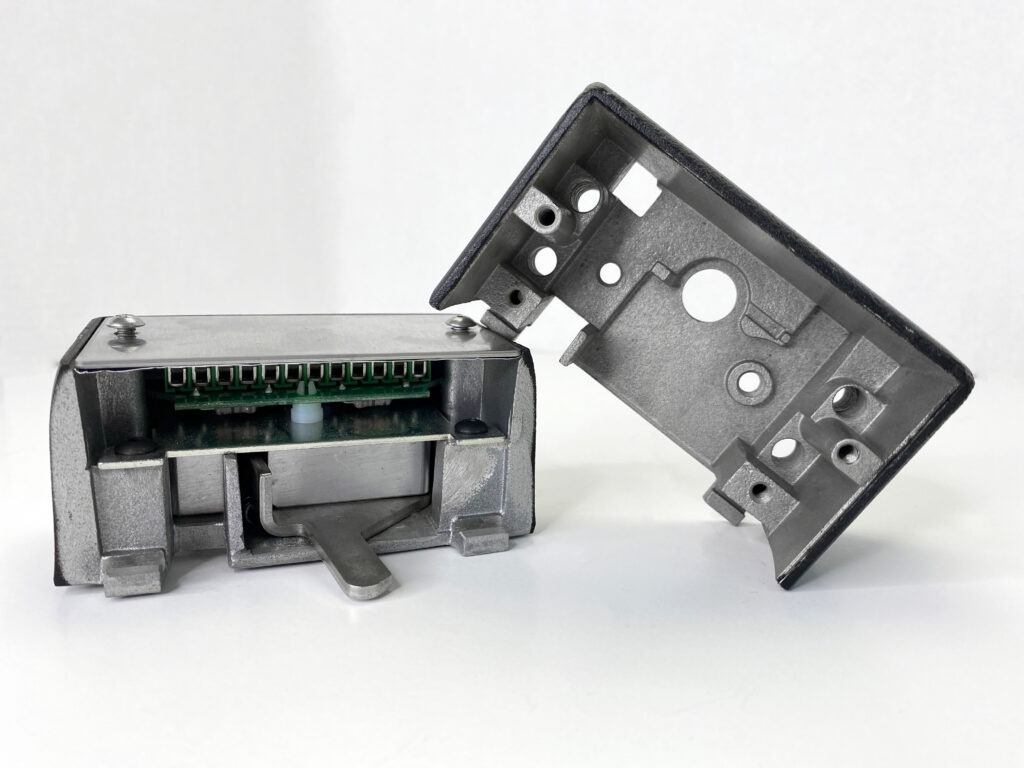

Compared to other casting methods, permanent mold castings hold tight tolerances, which results in a complex, near-net shape product.

If your product requires intricate features, you can add a quick secondary CNC machining operation. This is great to hit those tight details for circuitry and assembly!

Aluminum is highly conductive, making it ideal for overhead power lines and utility poles. While copper and silver are great electrical conductors, aluminum is lower cost, making it the perfect metal for telecommunication equipment.

For years, the telecommunications industry has been using aluminum in electrical equipment such as housings, enclosures, and even TEMPEST communication equipment.

Want to know if your project is right for aluminum permanent mold casting? Contact us today!

Our team will review your product and guide you in the right direction.