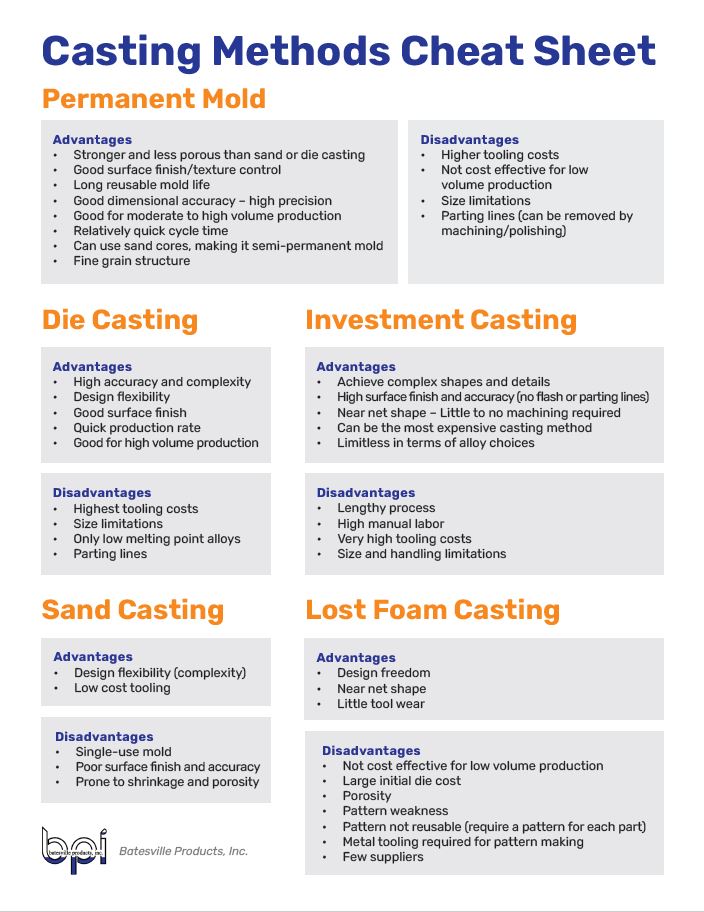

With so many casting processes, it can be hard to decide which one to use. Therefore, it is important to understand each option and how it relates to production costs, production volume, casting size, tolerance, surface finish, complexity and more.

Compare and contrast with us the 5 main casting processes (sand casting, permanent mold, die casting, investment casting, and lost foam casting), so you can make your decision based on the facts.

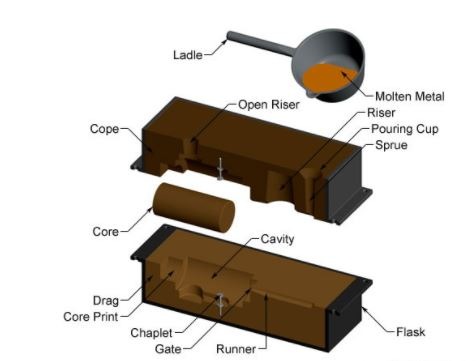

Sand casting is one of the most common casting processes. In this process, molten metal is poured into a mold made of compacted sand.

There are 4 specific types of sand-casting processes, each with their own advantages and disadvantages: green sand, nobake, coldbox, and shell.

Green sand is the most common sand-casting process. Its components include sand, clay, water, and other additives.

A benefit of green sand casting is that it can be used for high volume or short/prototype runs. It is cost effective for many metal applications.

However, green sand casting cannot hold as tight of dimensional tolerances and surface finishes as other processes. Therefore, it typically requires more machining to reach the final dimensions and surface finish than other processes.

This process involves a simple sand and resin mixture that cures at room temperature through a chemical reaction.

Benefits of the nobake process include good dimensional control, uniform strength, and size flexibility.

Unfortunately, the nobake sand mixture has a limited shelf life and you must be conscious of the sand temperature during the process. Overall, this process can be very costly.

This resin process cures at room temperature, using a gas or vapor catalyst.

Coldbox sand casting can achieve complex parts with low labor and energy costs.

However, this process is limited to small and medium sizes. The core box design is an important factor. It is also only cost efficient in high volumes.

This resin coated sand process requires heat to cure.

Benefits of shell sand casting include high dimensional tolerances and surface finish, opportunity for complexity, and a long shelf life.

Yet, shell sand casting is only available for small to medium sized parts. It requires metal tooling, making it only cost efficient in high volumes.

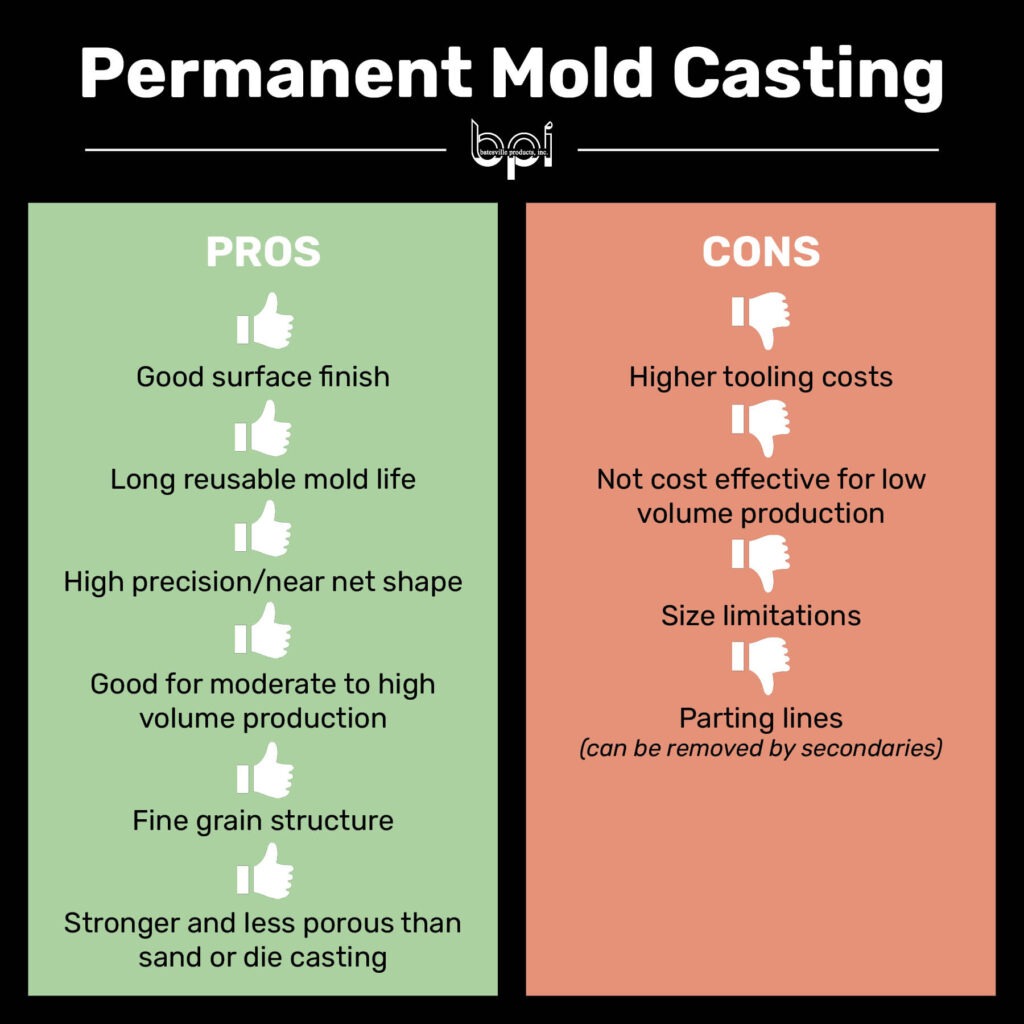

The permanent mold process is our specialty. It involves pouring nonferrous alloys into a preheated, reusable steel mold. The steel mold is prepared with a coating that prevents sticking and lengthens mold life.

Permanent mold foundries are typically cleaner than sand casting facilities because they do not involve loose sand.

Different pouring methods can be used in permanent mold that impact the success of your part: static standard/gravity pour, tilt pour, and reverse tilt pour. To learn more about permanent mold pouring methods, watch this short video:

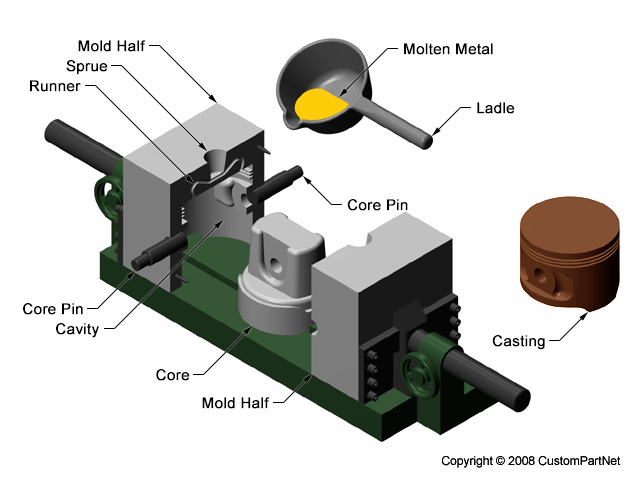

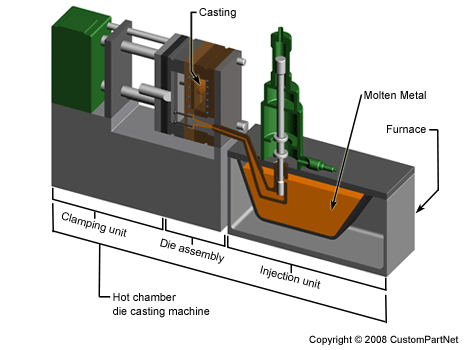

Die casting is similar to permanent mold casting. Die casting also involves a steel mold but uses pressure to inject molten nonferrous metals.

If you’re annually running tens or hundreds of thousands of parts, like an automotive company, you’re going to want to go with die casting.

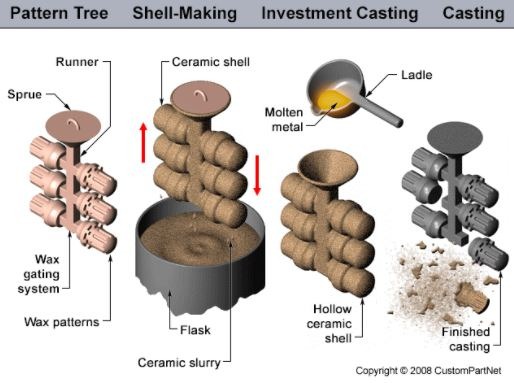

Investment casting uses a wax (or thermoplastic) pattern that is layered in slurry and stucco to form a shell. The wax is melted out of the shell, the now hallow shell is cured, and the metal is poured while the ceramic shell is still hot.

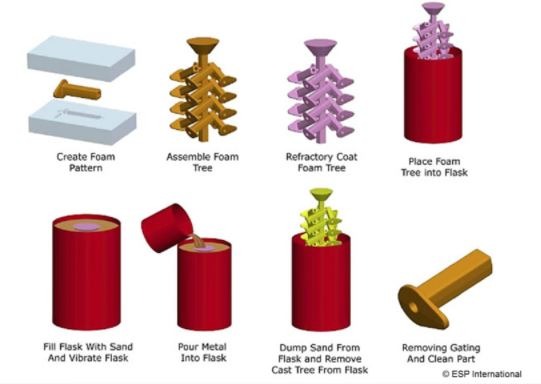

In the lost foam casting process, the part or clusters of parts are coated in a slurry and sand. They are vibrated to create a compact mold. When the molten metal is poured, the pattern evaporates, eliminating the need for cores.

Metal stamping is a common alternative to casting. It is best for simple parts, as it involves using high pressure to shape a sheet of metal into your desired part.

To kick start your next project, we have many allies in the casting business. We are happy to look at your next project and help decide what casting process is right for you.

Give us a call at (812) 537-2275 or you can email us at sales@batesvilleproducts.com