In the summer, we held a series of kaizen events to kick off our objective to install a polishing robot by the end of 2021. During this open discussion, our team excitedly shared ideas, collaborating to build a successful plan. We love how the kaizen events generated energy and promoted engagement throughout the company!

If you missed it, read about our kaizen events here.

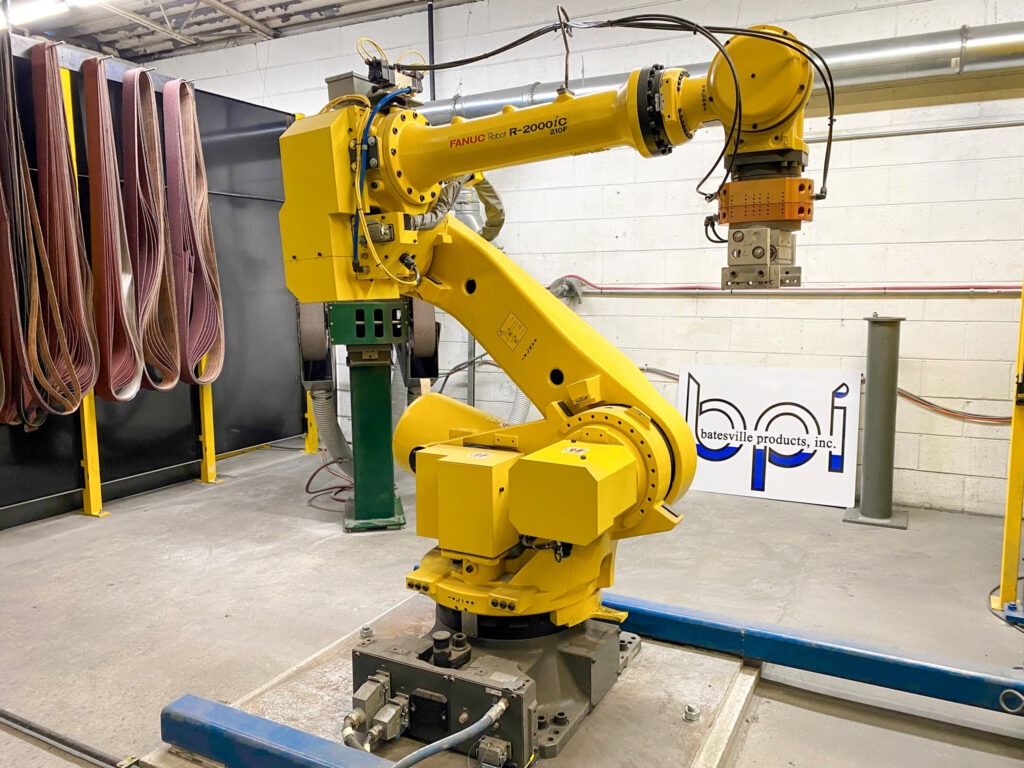

After months of planning, installing, and patiently waiting for parts, our polishing robot is finally in operation – watch the time lapse of this exciting process!

By integrating technology and innovation into our careful, hand-polish process, we are able to increase efficiency and decrease heavy labor – boosting overall company morale. Polished parts will be even more consistent and repeatable.

Just like how implementing robotic sawing decreased time spent cutting gating off castings, robotic polishing is great news for our customers. It will help get uniformly polished products out the door more efficiently!

We strive to continuously improve the quality of our services and customer satisfaction.

Therefore, we plan to continue implementing technology into our process. From sawing robots to polishing robots, to machine-loading cobots.