Recently, Batesville Products held a kaizen event surrounding our plan to implement robotic polishing.

“Kaizen” is the Japanese word for improvement, or change for the good, accurately describing these beneficial business events.

According to the Oxford dictionary, a kaizen event is “a Japanese business philosophy of continuous improvement of working practices, personal efficiency, etc.”

These events are collaborative, allowing every member to give their valuable input and explore all possible options, obstacles, and benefits.

Not long ago, BPI implemented robotic sawing. This advancement made our sawing process quicker, more accurate, and less labor intensive for our employees.

As part of our technology initiative, we plan to continue implementing robotics by installing a new polishing robot by the end of this year. This high-tech robot will create a more efficient, accurate process and high-quality finishes.

We held a kaizen event with the intention to decide where in our facility to install our new polishing robot.

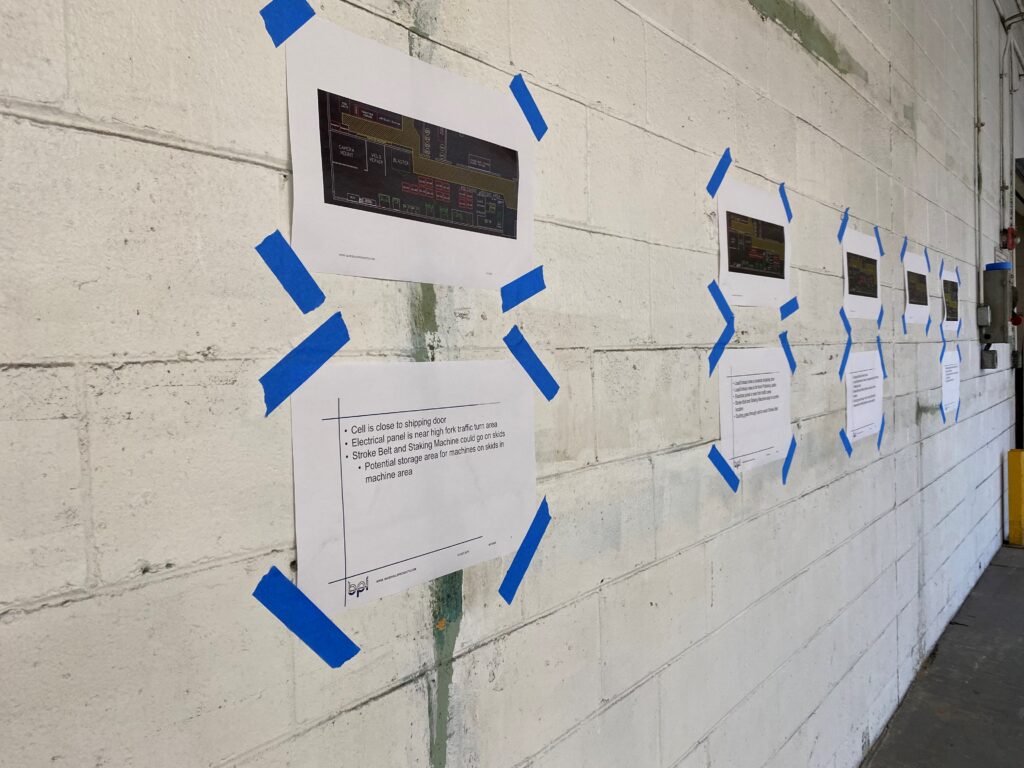

To kick it off, our Engineering Manager hung five different potential layouts on a blank wall in the polishing department. Under each floor layout option was a list of details such as potential pros, potential cons, and measurements.

“The great thing about kaizen events,” he said, “is that the answer usually isn’t on the wall.” While he taped five options on the wall, our Engineering Manager anticipated that the answer we were looking for would be a combination of options, or a completely new idea brought through conversation!

Our maintenance department also took part by taping outlines of the different layout options on the floor. This would help everyone envision the robot arrangement in action.

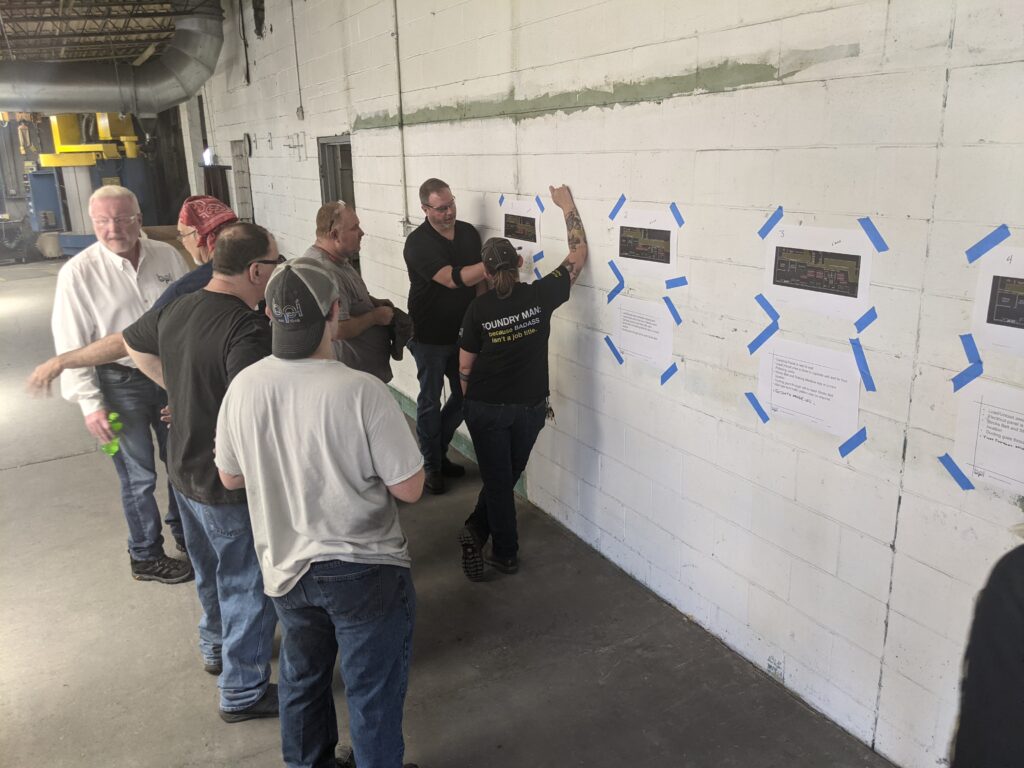

To begin the event, our polishing department halted their work and gathered around the images.

Then, our new Engineering Intern presented the different layouts, sparking conversation about pros and cons. Pens were distributed, and people wrote notes about each option on the wall.

Our polishing and engineering departments were eager to take part in this kaizen event! They discussed in-depth all aspects of the installation such as safety, venting, high traffic areas, work space, and more. It was a hot conversation topic in the office all week!

After thorough discussion, the original five options were narrowed down, and one was selected as the favorite. However, by gathering every stakeholder’s input, this option started to look different than when it did when it was originally hung on the wall.

With everyone’s comments in mind from the last kaizen event, we held another session. This time, the ideas presented were all variations of last event’s top choice. These new variations included all the feedback from last week and opened further discussion that led to our final decision.

Now we are ready to install that robot!

What made this event so successful is our employee’s eagerness to give input and collaborate to form new ideas.

The success of this event will set the stage for future BPI kaizen events. We love how this collaboration technique helps us make informed, thought-out, and well-received company decisions.

Reach out to our sales team to schedule a visit! You can email us at sales@batesvilleproducts.com or give us a call at (812) 537-2275.