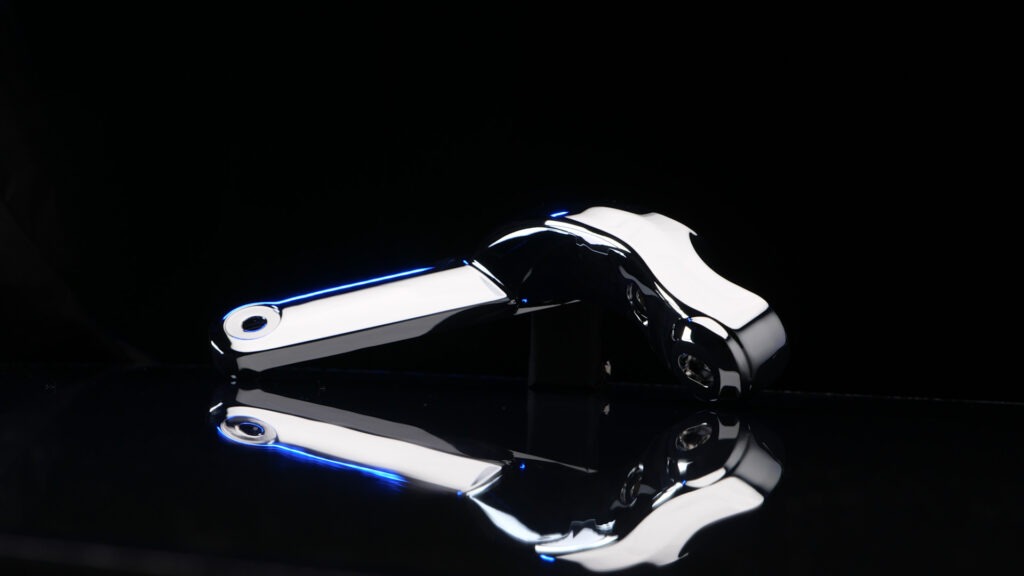

Plating is a beautiful finish for a highly cosmetic zinc or aluminum part. But do you know just how many steps there are to this finishing process?

We met with C.J. Nachtegall from Allied Finishing for a crash course on plating aluminum and zinc parts. In this article, we will take a deep dive in the chrome plating process.

Before a part can be layered with nickel, copper, and chrome, it must be polished and buffed for a very smooth surface. Any imperfections or uneven surfaces will be amplified once the plating layers are added. Therefore, you want a good casting from the start.

Plating requires a very clean part and facility to avoid any contamination. Parts are first cleaned. Then, they go through a chemical wash that will aid adhesion. This ideology is fairly similar to other finishing processes such as powder coating.

To begin plating, parts are loaded onto large racks, resembling a picture frame.

The design/size of your part, how much surface area you are plating, and plating thickness will determine the speed and ultimate cost of plating.

The part’s metal makeup is also a cost driver. For example, you can plate more zinc parts in one load than aluminum. This is because aluminum is more challenging to plate than zinc. While zinc binds well with copper (one of the three layers required for chrome plating), making it overall easier to plate, aluminum oxidizes quickly, making plating much more challenging.

On the rack, parts are put through a series of plating layers:

There are many chemically different variations of copper, nickel, and chrome layers. Each material comes with its own advantages and disadvantages, so expressing your end application is helpful to create the best possible performing part. Depending on your part, you may also use more or less layers.

And there you have it! After buffing, cleaning, coating for adhesion, and multiple metal layers ending with chrome, your part is beautifully chrome plated!

But keep in mind, plating does not have to end with chrome. There are many plating options for aluminum, including…

If you have an upcoming aluminum casting project that you’re considering plating, give us a call with any questions at (812) 537-2275 or you can email us at sales@batesvilleproducts.com