Casting defects. No one wants them.

There are countless types of casting defects, which have the potential to occur in every casting process. These can occur from slight changes to the metal, mold, temperature, environment, pouring method, etc. That’s why it’s so important to have a high-quality, expert supplier who knows what they’re doing!

Today, we will focus on 6 common porosity defects and how to avoid them.

Thank you to Brad Hohenstein and Ernie Coberly from Porosity Solutions (foundry consulting & learning center) for collaborating with BPI on this article. Thank you also to Monty Fullerton, Manufacturing Engineer at Batesville Products.

Surface porosity occurs on the outer surface, and often occurs due to contaminates that touch the exterior of the casting.

Examples include:

While there are a variety of surface porosity causes, you can often prevent the defect by properly maintaining the mold.

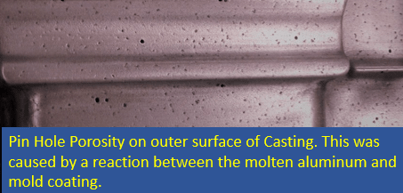

Reaction porosity is another type of external porosity. It is caused when the metal reacts with sand cores, core binders, mold coatings, or sprays.

This is easy to identify because it is always local and on the surface. Reaction porosity will not cause internal porosity defects.

For example, if a defect is caused by a reaction between the molten aluminum and the sand core, the porosity will outline the core like a halo. It will not spread anywhere else; it will only be near the sand core.

Gas hole porosity is an internal porosity caused by trapped air. The holes will have a rounded appearance.

Typically, gas hole porosity is very localized and is almost always caused by metal turbulence.

To fix this defect, reduce metal turbulence by adjusting your runners, sprues, gating, and pour time to slow velocity. The goal is for metal to flow rather than chaotically tumble.

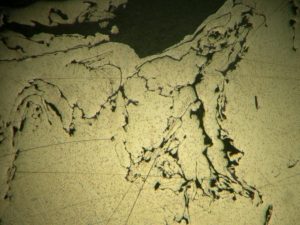

Oxides often appear as stringers intermixed with porosity holes. These can grow into large oxide inclusions, called spinels.

Like gas holes, oxides are also caused by turbulence. However, this defect occurs when that turbulence is mixing with oxides in the molten aluminum. This changes solidification in that area.

This can occur in any casting process, but the faster you fill the mold, the more prone you are to oxide defects.

To prevent oxide inclusions…

Oxygen will combine with magnesium or aluminum to create oxide defects. Alloys should be plunged and thoroughly distributed through the melt.

Be mindful of re-melting scrap metal or gating that have oxides on the surface.

Shrink is a solidification defect. The best way to combat it is by freezing or feeding the metal; Either get the metal there quicker or chill it quicker.

Shrinkage tends to be localized. This defect is common on complex castings. You will find it on the last place to solidify, often near the gating. Shrinkage also commonly occurs between thick and thin walls of the casting, or if you create a hot spot near the riser.

Shrinkage porosity tends to appear as elongated, rather than round. This is because shrinkage forms like frost on window. You’ll see dendrites slowly form together.

There are 3 levels of shrinkage porosity:

Shrinkage can be misleading because if you machine across a surface with shrinkage porosity, it will look great. However, if the casting is put under pressure, it will leak.

Hydrogen gas porosity is similar to gas porosity, because both appear as smooth and rounded holes. However, hydrogen gas porosity will be throughout the entire casting. It is not localized.

Hydrogen gas porosity is an internal porosity. You will not see it unless you break the casting surface – whether that’s by machining, sawing, or grinding.

Effects of Hydrogen Gas Porosity

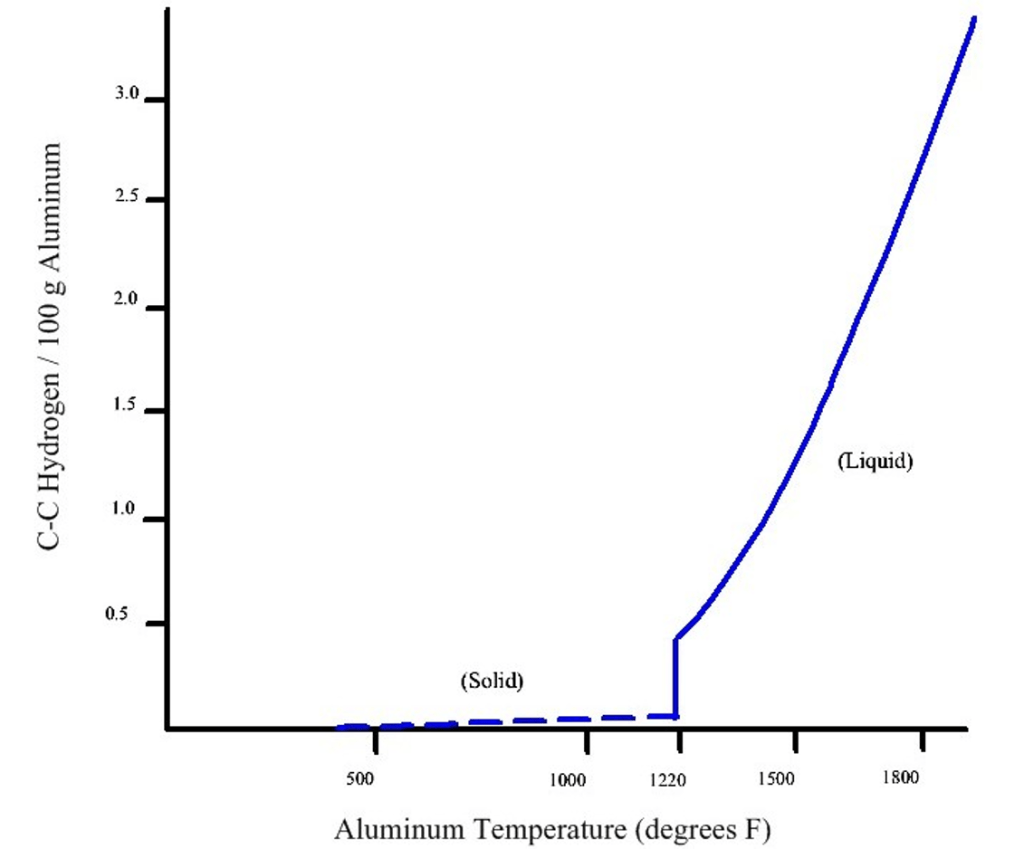

It is a reaction between molten aluminum and hydrogen in the air. Hydrogen molecules would rather be in molten aluminum than in the air.

Hydrogen is soluble in molten aluminum, but not in solid aluminum. So, as your casting solidifies, the gas trapped inside the casting creates porosity.

The reaction is correlates with moisture and metal temperature.

The rate that hydrogen enters the melt doubles for every 100 degrees above 1400. So, the ideal casting temperature is around 1375.

All molten aluminum will have hydrogen. The question is, which gas level does your part require?

To achieve zero porosity, you will need to perform an operation to degas the castings. Argon and nitrogen can be added to the melt. These gasses attach to or combine with hydrogen, then float to the top and burn off.

Completely gas free castings are not necessarily to your advantage. Gas can help alleviate shrinkage and aid in volume expansion. Depending on the product, some foundries will periodically add gas to the melt.

Remember, hydrogen gas porosity is internal porosity, so it will not be visible unless the surface is broken. Some parts that require a high-end surface and low tensile strength may not have hydrogen gas level requirements. Others that require machining and pressure testing may have strict hydrogen gas level requirements.

Perhaps the most beneficial tip when trying to identify porosity defects is to understand the location distribution. The location of porosity (drag, cope, gating, corners, etc.) will help determine which type of porosity you have, so you will know how to fix it.

More Tips