There are 3 common ways to pour molten metal into a permanent mold: static pour, tilt pour, and reverse tilt pour.

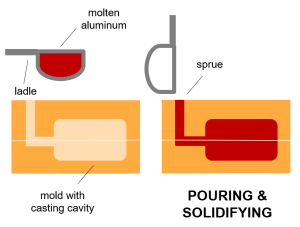

This is the traditional pouring method. The static standard or dump pour is just as it sounds: the metal is poured directly into the mold.

This pouring method is not machine controlled, which means the flow of the metal will depend on the operator. Therefore, castings may have inconsistent porosity due to varying turbulence and pour speed.

The static pour is most commonly used in sand casting. The diagram above shows a static pour into a sand mold.

However, static pour is sometimes used in permanent mold for small round parts where the center will be bored out, like wheels. Since static pour dumps directly into the center of the part, this section will have the most potential for gas and shrink. It is ideal to machine this center heavy section out.

For denser, more aesthetic parts, we recommend tilt pour or reverse tilt pour.

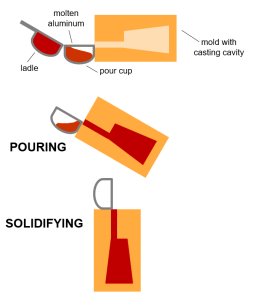

The tilt pour method is like pouring a beer down the side of a glass. It decreases turbulence, which decreases porosity. Air pockets or high porosity can make your part weaker, less dense, and difficult to machine and powder coat.

Unlike static pour, tilt pour is machine controlled. First, the operator pours metal into a pour cup. Then, the machine slowly tilts to allow the metal to smoothly flow into the mold. The machine sits completely horizontal to allow the metal to solidify in the mold. Finally, it returns to its vertical position, and ejects the casting.

By machine controlling the tilt timing and flow, you have better control of turbulence and porosity.

With static pour, part complexity is constrained by the mold cavities, how the mold opens, and cores. Tilt pour castings create opportunity for more complexity. You can add hydraulics, loose pieces, slides, and cores into a tilt pour permanent mold where you can’t in a static pour mold.

Tilt pour castings are ideal for products requiring high density and low-porosity. For example, permanent mold tilt pour castings are common in the medical equipment industry and food equipment industry. These industries require reliable, strong, sanitary parts with a high-end look.

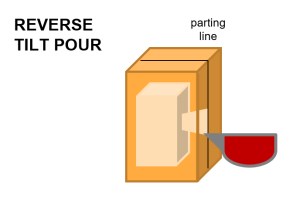

The reverse tilt pour is a mixture of both static pour and tilt pour. It’s almost identical to the tilt pour process, but the casting is center fed like a static pour (metal going into a riser, directly into the part).

Reverse tilt pour castings reap the benefits of a machine-controlled tilt pour, bringing more consistency and less turbulence.

Like a static pour, you are feeding material into the center of the part. Therefore, you target a heavy section that will be removed from the casting. In the example below, the thick riser will be the last to solidify, pulling all the gas and shrink into this section that will be cut off.

Reverse tilt pour casting is ideal for large castings with heavy sections and consistent geometry or center symmetry, like a wheel or a thick square lid.