Nondestructive testing (NDT) refers to inspection methods that verify the properties and quality of a casting without damaging it, so that the casting is still usable after inspection. NDT methods can detect flaws, cracks, voids, or porosity.

Here are 5 common nondestructive testing (NDT) methods used for aluminum castings.

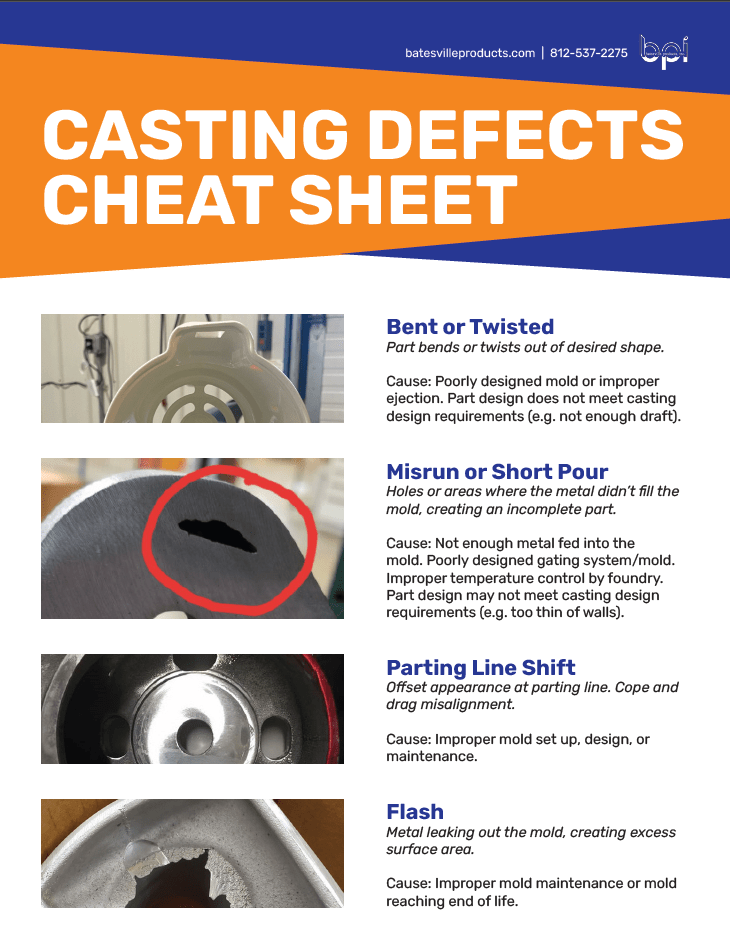

Visual testing is the simplest form of NDT. It involves looking over a casting for any signs of tears, cracks, voids, bends, flash, porosity, etc. Foundries often perform visual inspection checks as a casting goes through the production process.

For visual inspection, you can use magnification tools, borescopes, or cameras.

Liquid dye penetration inspection can detect cracks, porosity, or surface-breaking defects.

During liquid penetration testing, a dye is applied to the surface of the casting. This dye will seep into any cracks or defects. After wiping off the excess dye, a developer is applied to draw out the dye from the defects, making them visible under ultraviolet light.

Dye penetrant testing is very common due to its simplicity and effectiveness.

Radiographic testing uses X-rays to produce an image of the casting’s internal structure.

X-ray testing can identify internal defects that are not visible on the surface, such as porosity, inclusions, or internal cracks. It verifies structural integrity of the casting, which is important in industries such as construction or aerospace.

Neutron radiographic testing is similar to X-ray radiography but uses neutrons instead of X-rays, providing different contrast and penetration capabilities, useful for certain materials.

Ultrasonic testing sends high-frequency sound waves through the casting. These waves reflect off any internal defects and are detected by a receiver. This inspection method precisely identifies the location and size of defects.

Ultrasonic testing can detect thickness measurements, cracks, voids, porosity, or inclusions.

Pressure testing is another common and simple inspection method. A pressure test uses air or water to pinpoint leaks, failures, or deformities. Pressure testing ensures the integrity and safety of castings that operate under pressure, such as oil and gas equipment.

Pressure decay testing is similar to a traditional pressure test, but it monitors pressure drops over a time period. Other leak testing methods include hydrostatic testing, bubble testing, or tracer gas testing.