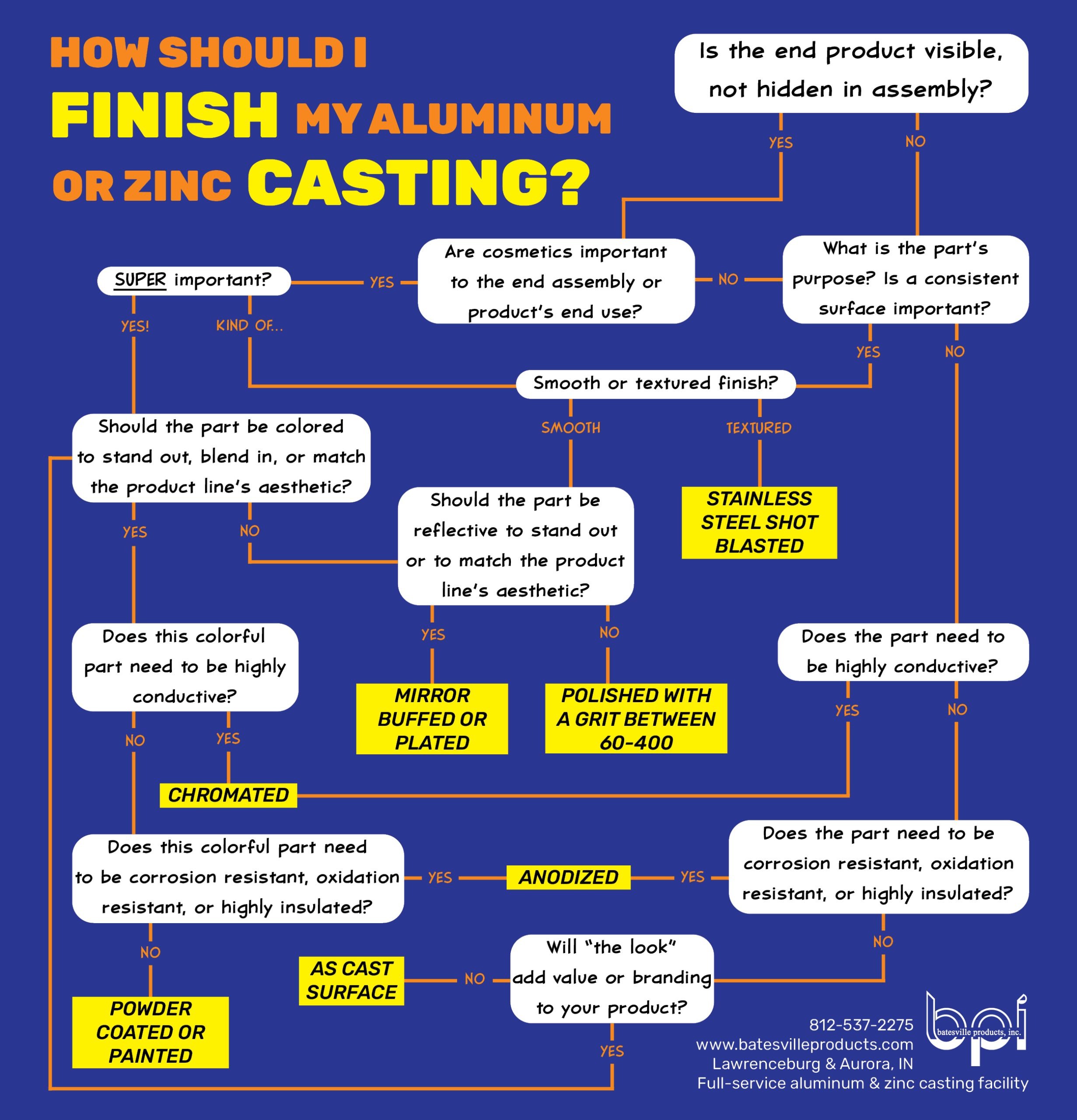

With so many finishing options, how do you choose? Custom parts require custom solutions. This simple flowchart will help you start to find your ideal finish.

There are 7 common ways we finish aluminum and zinc castings:

Permanent mold products have a high quality surface finish out of the mold, so they do not always require a finishing operation. This is one way a permanent mold casting can save you money!

We use various grit strengths to give castings a finer surface.

This creates a consistent, textured surface.

This process makes parts, especially zinc products, extremely reflective.

This common finish creates a colorful, stand-out product.

Chromated parts can be colorful and are highly conductive.

Anodized products are not only colorful, but also receive extra protection. They are corrosion resistant, oxidation resistant, and highly insulated.

Give us a call. We cast, machine, and polish permanent mold aluminum and zinc castings every day. Our casting experts will be happy to assist with your project!