Need a quote but not sure where to start? That’s what we’re here for!

In this blog, we will walk you through everything involved in the quoting process, from what details your supplier needs, to questions you should ask your supplier.

Whether you are coming to us with a concept design or ready-to-build project, you should supply project details that allow you to shop around supplier options and make the best decision.

It is beneficial to tell your supplier about your part’s end application. We want the big picture! BPI has experience in a lot of industries, so when you tell us about how your product will be used, it will help us ask more relevant questions to better serve you. For example, it is helpful for the supplier to know if the product is going to be assembled, hidden, or cosmetic. This will help us help you make finishing decisions.

If you are looking to improve an existing part, it is important to share what issues you are experiencing with your current supplier. This will help align expectations.

Once we understand your concerns, we may create an updated model to help plan your “new” tool. For example, we can take any existing part, scan it with 3D technology, and create a detailed, accurate 3D model of your part. This model will allow us to clearly identify where we can make adjustments.

No problem! We have converted die cast projects into permanent mold projects before.

If you are starting a new project, there are a couple things you should talk to your supplier about to ensure an accurate quote…

While the timeline always depends on the project, it is typical to expect a quote in 3 to 10 days. At BPI, we try to provide quotes within 5 days.

Quotes are often very custom in the casting industry, requiring a lot of time and effort. If you are requesting JUST a casting, your quote turnaround time may be quicker due to the simpler process. However, quotes that involve heat treating, polishing, machining, coating, and more secondaries take longer to develop because they involve more details.

We want to make sure the quote is comparable to competitors, is clear and transparent, and includes every detail or process required to make the best part possible. Overall, we make sure the quote is self-explanatory and outlines what you want and need to know.

Therefore, walk through timeline, scope, operations, and EAU with prospective customers to showcase how these operations minimize costs.

At BPI, we have created a unique, high-level algorithm that includes all the information we need to smoothly manufacture your part. Each step of the process is plugged into the algorithm and outputs your custom quote.

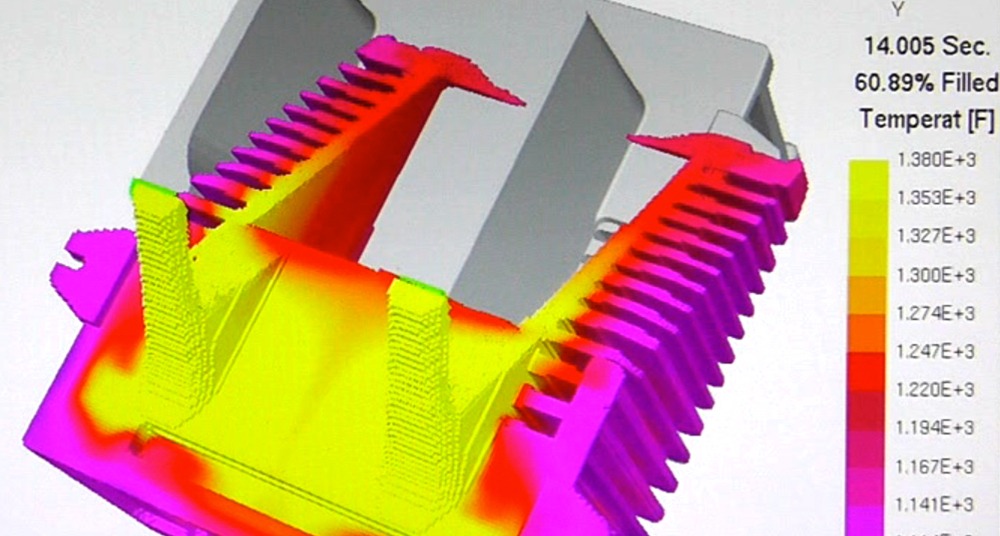

Two important aspects are calculated in quoting tooling: the mold design and the FEA.

When we look at the mold design, we make sure the casting is doable. Therefore, we look at aspects such as cavities and runners.

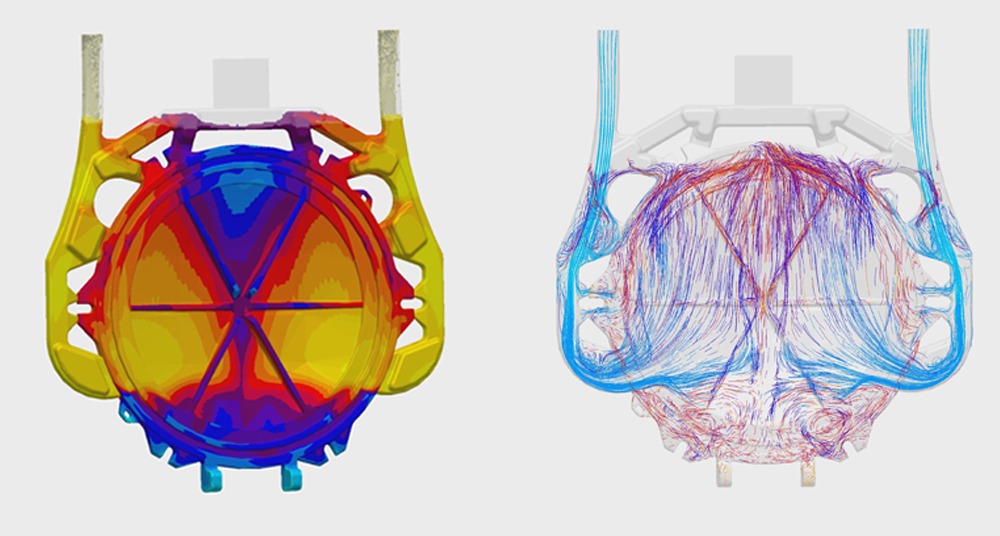

A FEA is a simulation that predicts the pouring process by modeling the tool. This software predicts how metal flows, the distribution of heat, air entrapment, etc. Running a FEA will inform if we need to make any adjustments to the mold such as venting, gating, or ejecting.

Not all foundries use a FEA, but we have found that it is a critical part of the casting process! We run this analysis on every tool because we want to ensure that we create a quality part on the first try. It helps avoid wasting time, money, and effort.

Next, we look at costs associated with pouring the casting. A lot of systems go into making sure we develop an accurate cost and rate:

Machining can be simple or complex. We like to look at machining upfront to see whether we can cast a feature, or if it must be machined, to ensure we save time and money.

Machining cost is related to…

This happens all the time. As soon as you think there may be modifications to your process, make your foundry aware! The sooner they know, the better they can predict how this modification may affect the operation and amend the process.

Our high-level algorithm make sit easy to plug in adjustments and see if/how it will affect your quote. Therefore, it is easy to adjust on the fly.

Keep in mind: Making changes may or may not affect your quote! For example, we had a customer who wanted to add a pressure test in their operation. Our solution was to insert this test during the machining process. While this changed the operation, it did not change the original quote.

Overall, we aim to create a quote that is manufacturable, comparable to competitors, cost-efficient for the customer, and meets expectations. We want to ensure the customer understands all the aspects that go into the production of their part and the cost of each process.

Ready to start your quote? You can email us at [email protected] or give us a call at (812) 537-2275. You also can skip right to this form.